Screw Compressor Central Chiller

Chapter 3: Installation

27

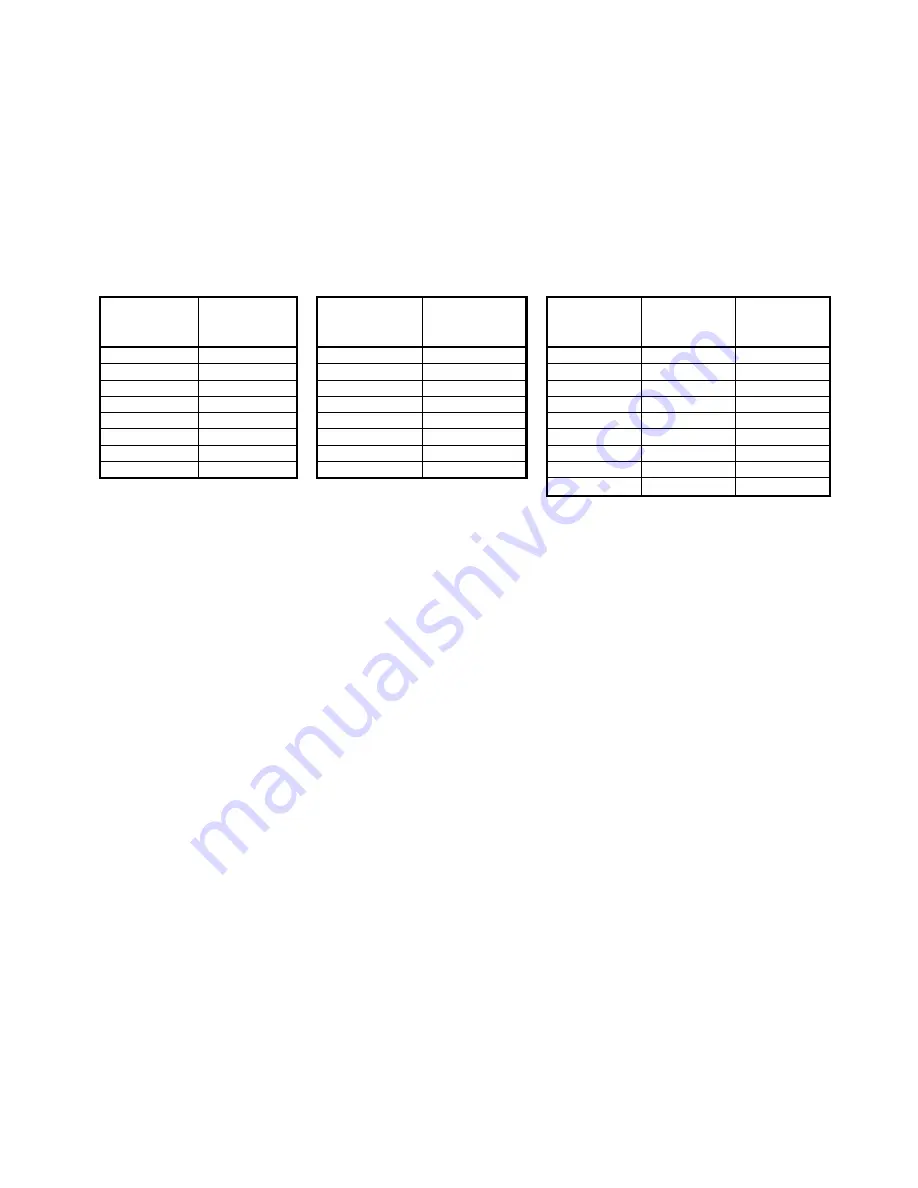

Refrigerant Charge Determination

The approximate amount of refrigerant charge required by the system varies based on the

total length of the refrigerant lines and the size of the chiller. Referring to Figure 6,

determine the amount of charge based on discharge and liquid line sizes and lengths. Add

these four numbers together to find the total operating charge.

Figure 6: Refrigerant Charge Determination (per circuit)

Chiller Charge

Air Cooled Condenser

Charge

Field Installed Piping Charge

Horsepower

Lbs. of R134a

Horsepower

Lbs. of R134a

Pipe O.D.

Inches

Discharge

Line

R134a (Lbs.)

Liquid Line

R134a

(Lbs.)

35

20

35

19

7/8”

1.0

24.3

40

25

40

24

1 1/8”

1.7

41.4

50

30

50

29

1 3/8”

2.6

63.0

60

35

60

29

1 5/8”

3.6

89.2

70

40

70

36

2 1/8”

6.3

155.1

80

50

80

43

2 5/8”

9.7

239.2

90

55

90

50

3 1/8”

13.9

341.4

110

65

110

58

3 5/8”

18.8

461.8

4 1/8”

24.4

600.2

Based on 100 feet of pipe, 100°F Liquid, 100°F

Discharge

Verify Correct Charge

The final operating charge must be verified by running the system and checking the liquid

line sight glass as well as the sub-cooling.

The system should have at least enough load to run one compressor fully loaded in order to

properly verify operating charge.

Typical condensing pressure with a full load and 95°F ambient air over the condenser will be

170 PSI or HFC 134a. Each circuit should be charged to maintain 10°F sub-cooling under

these conditions.