F-Range Type L-850C Style 3 Inset Lights

Maintenance

2006 ADB Airfield Solutions, Incorporated

96A0285D

Page 4-3

All rights reserved

Issued 04/13

2.

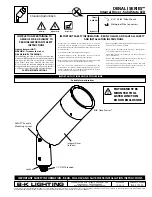

Clean the outer surface of the prism (3) using liquid glass

cleaner. If the prism is coated with a substance impervious to the

cleaner, apply a suitable solvent sparingly with a wad of cotton or

a patch of cloth. After the solvent has acted, remove the

softened coating with a clean piece of cotton or cloth. Dry the

prism with gently, dry, oil-free compressed air at a pressure no

greater than 10 psi (69 KNt/m

2

) to evaporate or remove all

remaining cleaner.

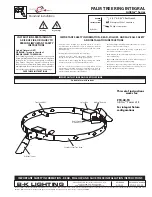

When retorquing mounting bolts, apply one drop of Grade AV Loctite

to each of the six 3.8-inch- (9.525-mm-) diameter mounting bolts.

Torque the bolts to 185

5 inch-pounds (20.902

0.565 Nt-m).

Torque the bolts across the corners.

See Figure 4-1. To torque the outer bolts across corners, tighten

bolts in noted sequence: #1 and #4, then #2 and #5, then #3 and #6.

NOTE:

Applying more than one drop of Loctite to the screw and bolt

threads will create future difficulty in removal of the bolts.

NOTE:

After several relampings, threaded holes may accumulate

with dirt and excessive Loctite. If this occurs, screws may not seat

properly. Clean holes with light weight oil or diesel fuel using a small

fiber brush. Wipe the holes clean with alcohol to remove all oil or

diesel fuel and dirt. Clean with dry, oil-free, low-pressure air.

Figure 4-1 Sequence for Torquing Mounting Bolts

Cleaning Light Channel and

Prism

(contd.)

Retorquing Mounting Bolts