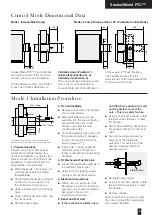

BLACK

GREEN/

YELLOW

BROWN

BLUE

ELECTRICAL THERMAL RELEASE

(SPRING BIASED TEST SWITCH)

ELECTRICAL THERMAL RELEASE

(SPRING BIASED TEST SWITCH)

TF 72

°

C

TF 72

°

C

2

1

S2

S3

S4

S5

S6

S1

N

E

M

L

VOLT FREE CONTACT

CHANGES OVER WHEN

DAMPER RELEASED

RATED 24V 3A

VOLT FREE CONTACT

CHANGES OVER WHEN

DAMPER RESET

RATED 24V 3A

SUPPLY

24V A.C. OR D.C.

TYPICALLY 7W (MOTORING) 2W (RESET)

COMMON

NORMALLY CLOSED

NORMALLY OPEN

NORMALLY CLOSED

NORMALLY OPEN

COMMON

VOLT FREE CONTACT

CHANGES OVER WHEN

DAMPER RESET

RATED 240V 2A

COMMON

NORMALLY CLOSED

NORMALLY OPEN

2

1

S2

S3

S4

S5

S6

S1

N

M

L

VOLT FREE CONTACT

CHANGES OVER WHEN

DAMPER RELEASED

RATED 240V 3A

VOLT FREE CONTACT

CHANGES OVER WHEN

DAMPER RESET

RATED 240V 3A

SUPPLY

220 - 240V A.C. 50/60Hz

TYPICALLY 8W (MOTORING) 3W (RESET)

COMMON

NORMALLY CLOSED

NORMALLY OPEN

NORMALLY CLOSED

NORMALLY OPEN

COMMON

5

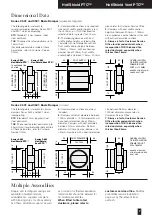

Smoke/Shield PTC™ Vent/Shield PTC™

Smoke/Shield PTC

Application and

Wiring

Mode 1

(Manual System)

Manual opening.

Spring instant closure via mechanical

fusible link.

(Smoke/Shield version only, Vent/Shield not available.)

Mode 5

(24V System)

Power On – Damper motors open.

Power Off – Spring closure or via

Electrical Thermal Release.

External mechanical position indicator

with pointer.

Release Time

≈

16 secs.

Reset Time

≈

140 secs.

(Connect 24V via a safety isolating transformer.)

Vent/Shield PTC™ dampers and

associated control modes 5 and 6

are reverse acting with spring action

opening.

Mode 6

(230V System)

Power On – Damper motors open.

Power Off – Spring closure or via

Electrical Thermal Release.

External mechanical position indicator

with pointer.

Release Time

≈

16 secs.

Reset Time

≈

1c secs.

(To isolate from main power supply, the system must

incorporate a device which disconnects the phase

conductors, with a least 3mm contact gap.)

General

One metre of halogen free low smoke

and fume electric cable is also

included with each control mode for

convenience of on site wiring. This

also provides the distinct safety

advantage of all electrics terminating

outside the duct, eliminating potential

in-duct fire hazards from wiring faults.

The Electrical Thermal Release is pre-

wired with 0.5m halogen free low

smoke and fume cabling to Control

Modes 5 and 6.

A Manual test switch fitted on the

ETR allows periodic operation of

damper simulating actual fail-safe

release under smoke/fire conditions.

Smoke/Shield and Vent/Shield

PTC™ Dampers and associated

Control Modes 5 and 6 are

available without the ETR where

thermal operation is not required.

If integrating this unit with an Actionpac

damper control system (LNS or EM)

please refer to the relevant catalogue

and specific project details.

For non ETR applications refer to

specific product label on Mode, prior

to electrical connections.