2

All wiring should be carried out in

accordance with the wiring details

provided, the IEE and BS regulations,

by a competent person.

Care must be taken when installing

and inspecting dampers, as they may

close without warning due to a variety

of reasons. Particularly this may be in

the case of loss of electrical power, or

fire signal to temperature rise in the

ductwork. This is their prime function.

Do not introduce any items, fingers or

limbs between the blades.

Prior to handling, check the weight of

the unit and adopt suitable handling

techniques.

PTC Dampers

Health and

Safety

The PTC™ range of dampers are

suitable for both horizontal and

vertical applications, for airflow in

either direction.

PTC™ dampers to their maximum

width and height dimensions can be

used where the operating total

system pressure is up to 1500 Pa

and duct velocities to 15m/second.

All Smoke/Fire dampers are life safety

products and should be treated with

care during handling, storage and

installation.

PTC™ dampers are designed for

applications in normal dry filtered air

systems and should be subject to a

planned inspection programme,

cleaning and light oil lubrication in

accordance with good industry

practice. When exposed to fresh air

intakes and/or inclement conditions

this may need to be performed more

regularly based on experience gained

from previous inspections.

Specialist or aggressive environments

may be unsuitable for this type of

damper. This should have been

checked with the Customer Service

department at the time of order. If

there are concerns this should be

addressed before installation.

For assistance with applications other

than those described please contact

our Customer Service Office.

Please note all installations must be

carried out in accordance with the

approval of the relevant local

authority.

General Information

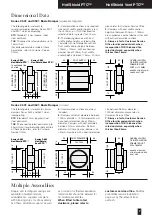

All installations must be made in

accordance with approval of the

relevant local authority and if

HEVAC/HVCA frames have been

supplied, also in accordance with

HEVAC specification HVC 6/5/83,

extracts of which are given below.

Installation frames are delivered to

site as a complete assembly with the

appropriate PTC™ damper fitted

therein.

The damper shall be installed

centrally in the thickness of a

brickwork or concrete surrounding

wall or floor, or in the case of thick

walls or floors, so that the centre line

of the frame is at least 50mm, but

not more than 75mm, away from the

nearest face of the wall or floor, in

which the assembly is mounted.

Care must be taken not to backfill

past the line marked on the label

on the shroud. If this does occur

it will inhibit the fitting and

removal of the interface.

(See diagram on the right).

The four tabs (building ties) forming

each fixing point shall provide a

positive fixing into the structure.

In brickwork or blockwork walls the

tabs shall be bent out and solidly

built into the mortar joints between

the brickwork or blockwork.

In the cases of reinforced concrete

walls or floors, the tabs shall be bent

out and tied with wire to the

reinforcing bars, which will be

deliberately left protruding into the

opening.

The gap between the installation

frame and builders work shall be

backfilled with mortar or concrete on

both sides of the flange.

Adjacent frame assemblies must be

separated by builder’s work of a

minimum thickness of 225mm

(between installation frame upstand

flanges unless approval has been

previously obtained from the

appropriate Authority).

In no case shall the HEVAC/HVCA

frame and damper assembly be

held in position merely by the

adjacent ductwork, and it should be

noted that in reinforced concrete

structures (especially floors), it will

not be sufficient to only backfill

between the damper installation

frame and surrounding opening

with mortar or fine aggregate

concrete mix without provision for

tying in the frame to the

surrounding reinforced concrete

structure.

When fitting the ductwork care

must be taken to ensure that the

ductwork is independently

supported and not relying on the

damper as a structural anchor, all

in accordance with Ductwork

Specification DW144. Access

doors should also be fitted as

required by DW144.

For Hot/Shield PTC and

Hot/Shield Vent PTC dampers

fitted to thickened fire rated

ductwork, please refer to notes

on page 7.

Damper Installation

Backfill

Limit Line

on Label

Damper Drive Shroud