3

Smoke/Shield PTC™

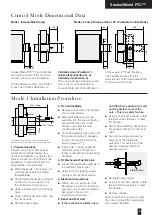

Mode 1 Installation Procedure

315

±

20mm

40

±

*

75mm

5mm

130mm

135mm

108

130mm

TOP

*This dimension will vary on circular damper. Select

dimension to give smoothest radius on bowden cable.

1. Prepare ductwork

Prepare ductwork for Mechanical

fusible link as detailed below. (For

ductless installations, a suitable sized

plate or bracket must be fitted to the

installation, to allow the fusible link

fixing details to be achieved).

●

Within the Mode 1 kit of parts, is a

self adhesive fusible link drilling

template label.

●

This template should be positioned

on the duct in accordance with

the dimensions shown above.

●

Using a 3.0mm dia bit, drill 2 fixing

holes.

●

Using a 25mm dia hole cutter, drill

the central hole.

●

Remove sharp edges.

248

28

56

84

260

100

112

12

108

70

25

130

108

130

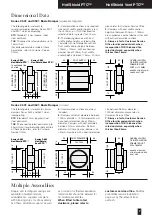

Smoke/Shield PTC™ Control Modes

are located outside of the ductwork

for ease of access and installation.

Control Modes 5 and 6 can be fitted

in any one of three orientations i.e.

Vertically down (Position 1)

Horizontally (Position 2), or

Vertically up (Position 3).

This can be simply and easily carried

out on site, by repositioning the

Location Plate and Control Mode on

to the

snap

lock™ Drive Interface.

This flexibility ensures that the

damper and control mode require the

minimal amount of room.

Mode 1 (Smoke/Shield only)

Modes 5 and 6 Three position 180° (Pivotable Control Mode)

Control Mode Dimensional Data

2. Fit Control Mode

●

Remove transit plate from damper

shroud, and discard.

●

Slide the interface and mode

assembly into the shroud, having

ensured that the slots in the

interface case and the drive

coupling are in line.

●

Push the assembly fully home until

the spring retaining pin engages

through the location hole in the

shroud (

snap

lock™ ).

●

(The mode 1 option, unlike the

mode 5/6, does not have the

facility of alternative actuator fixing

positions).

3. Fit Mechanical Fusible Link

●

Locate the fusible link assembly in

the prepared hole in duct.

●

Using the 2 self tapping screws

provided, secure the assembly.

4. Electrical Connections

●

Where use is to be made of the

integral microswitch for indication

purposes, this should be wired as

described in the section

‘Application and wiring’.

5. Reset and Test Unit

●

If the mechanical fusible link is

not fitted to the ductwork, it will

not be possible to reset the

unit. – This is a safety feature.

●

Using a 14mm A/F spanner, rotate

the input shaft clockwise to reset

the damper.

●

NOTE: After resetting, never leave

the spanner attached to the reset

shaft.

●

Test unit by simply unscrewing

wing nut of the fusible link

assembly. This will result in the

damper releasing. Check for

damper closure.

FUSIBLE LINK

●

Re-tighten the wing nut.

●

Using a 14mm A/F spanner, rotate

the input shaft clockwise to reset

the damper.

●

Remove spanner.

Note: It will not be possible to reset

the control mode if the fusible link is

not correctly installed.