Suburban Dynaline 3 A&E Manual 12/2021 Rev.2

29

Built-in Thermostat Control – Heat Mode

Initial Lighting Instructions

1. Open the manual shut-off valve. The valve is fully open when the

handle is level or parallel to the gas line. Never attempt to operate unit

with manual valve partially closed.

2. Depress “System” key pad until heat lamp

is illuminated. (See

Figure 32

.)

3. Depress “Fan” key pad until desired speed

lamp is illuminated. (See

Figure 32

.)

4. Set thermostat to desired setting by

depressing temperature-indicating arrows

until desired temperature is displayed.

5. If the thermostat circuit is closed at the

setting chosen in Step #4, the ignition

sequence begins. After approximately

20-25 seconds, the main burner should

be established.

6. After ignition, the operation of the

unit will be controlled automatically by

the thermostat.

To Shut Down for an Extended Period of Time

1. Depress “System” key pad until standby lamp is illuminated.

2. Close manual shutoff valve.

Sequence of Normal Operation – Heat Mode

1. When heat is required, the thermostat closes and energizes the combustion

air motor and the supply air motor.

2. As the blower reaches approximately 90% of the normal RPM, the

pressure created by the combustion air motor causes the diaphragm in

the pressure switch to move, closing the contacts. This completes the

electrical circuit to the input of the module board and a 10-second

warm-up period for the glo-bar is established. During the warm-up period,

the glo-bar comes on for 10 seconds, then the valve opens. The glo-bar

remains on another 3 seconds after the valve opens and then goes off.

When the valve opens, it will remain open for 6 seconds. Gas will flow

to the burner and be ignited by the glo-bar.

3. If the main burner flame is sensed, the burner will remain on until

the thermostat is satisfied. If the flame is not sensed, the gas valve closes

and the ignition sequence is automatically repeated two (2) times. If the

burner does not light during this trial for ignition period, the unit will

lock out for one (1) hour and then re-set automatically.

NOTE:

If lock-out should occur, the unit can be re-set manually by selecting

Standby and then selecting Heat Mode. The ignition procedures can now

be repeated. Should repeated lock-out occur, shut unit down and contact

service agency.

4. When the thermostat is satisfied, the valve closes. The combustion

air motor will remain on for a 30-second purge cycle, then goes off. The

room air blower will continue to operate for approximately 90 seconds at

which time the circuit is opened and the room air blower goes off.

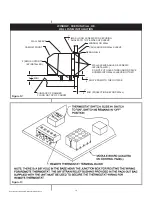

OPERATING INSTRUCTIONS

DIGITAL KEY PAD

CONTROL

Figure 30

SYSTEM

SYSTEM

FFAN

AN

ST

STANDBY

ANDBY

HEA

HEATT

COOL

COOL

FFAN ONL

AN ONLYY

HIGH

HIGH

LOW

LOW

SET

SET

COOLER

COOLER

W

WARMER

ARMER

SER

SERVICE SYSTEM

VICE SYSTEM