9

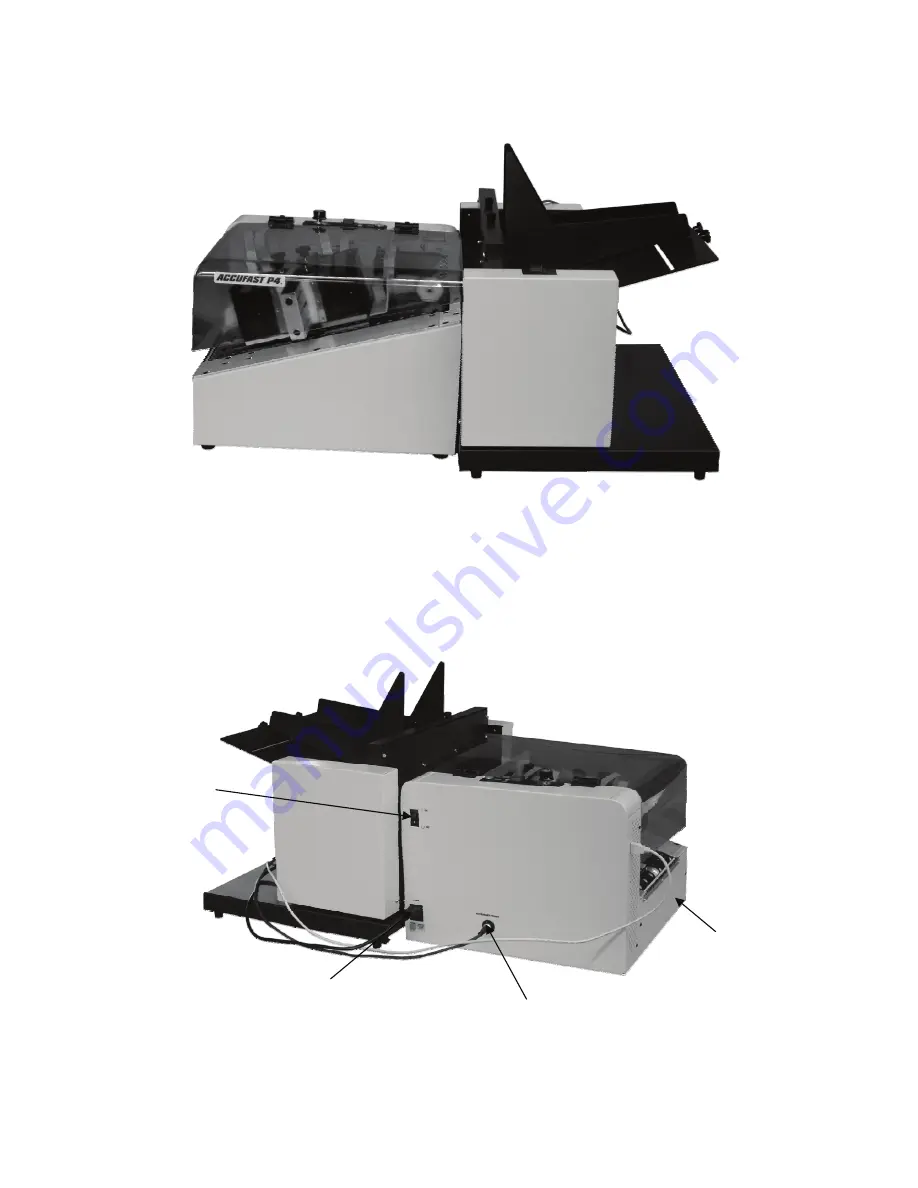

The Wide Format Feeder (ACCUFAST FX) merely sits on a stand at the

input end of the P4. To set it up:

1. Unpack the Feeder and the Stand

2. Place the Stand against the Printer’s input end

3. Set the Feeder on the stand and slide it up to the printer.

4. Plug the Feeder into the outlet on the rear of the Printer.

Power Switch

Power Cord

Fx Feeder power

USB Cable

Содержание P4

Страница 1: ...ACCUFAST P4 Small Envelope and Card Printer User s Guide and Operating Manual...

Страница 29: ...29...

Страница 30: ...30...