M 0496 GB

-

10

ERR. 36 Rising edge fault detected for ENCB. 1. Check positioning of the encoder card.

2. Clean the encoder decal.

ERR. 37 Detected irregular behaviour of the

ENCA falling edge with respect to

the reset rising edge.

1. Check positioning of the encoder card.

2. Clean the encoder decal.

3. Move the encoder card up or down.

ERR. 38 Detected irregular behaviour of the

ENCB falling edge with respect to

the reset rising edge.

1. Check positioning of the encoder card.

2. Clean the encoder decal.

3. Move the encoder card up or down.

STOP

[STOP] button pressed during test.

1. Repeat the test.

3. Encoder count test

Press:

[MENU]

[

]

[ENTER]

The word [dIAgn.] appears

[ENTER]

Confirm

After a brief LED and display test, the wheel position appears on the right-hand display, which must vary in the range

0%127 in a full turn.

On the LED matrix

↑

must appear in clockwise direction and

↓

in anticlockwise direction.

GAUGE CALIBRATION

(use an average size wheel with steel rim i,.e. 14” x 6” ± 1”) - see

CALIBRATION

and

CHECKING AND CALIBRATION OF THE GAUGES

-

DIST.= between 50 and 1000 by pulling out distance gauge completely

DIA= between 50 and 1000 by opening diameter gauge wide

Calibrate gauges and check accuracy.

Tolerances:

DIST.= 5 mm

DIAM.= ± ½”

CALIBRATION

(see

CALIBRATION

)

Use the same wheel as for gauge calibration

Set accurate measures, in manual mode if necessary

Make self-calibration

CHECKING MACHINE OSCILLATION

After running autocalibration, press [STOP] to return to the standard measuring frame.

Without locking the wheel, measure the machine oscillation as follows:

[MENU]

[

]

[ENTER]

[MENU]+[STOP]+[MENU]

Press in sequence in maximum 5 sec.

The words [Lan] [ci] appear

[ENTER]

Confirm.

The letters [t.L.] [ 10] appear

[START]

A cycle of 10 spins is run with automatic calculation and display

of the maximum oscillation (max. per/- 2 g).

[ENTER]

The following appears [Ini] [~120]: indicates the average unbalance measure

ment start speed in rpm.

[ENTER]

The following appears [End] [~100]: indicates the average unbalance measure

ment end speed in rpm.

N.B.

: The difference between the unbalance measurement start and end speed must never be more than 30 rpm.

[ENTER]

End of test.

[STOP]

Return to the standard measuring frame

If you wish to run more than 10 automatic spins, when [t.L.] [10] appears press the buttons [+]/[-] to select the desired

number in the range 5%999.

CHECKING MACHINE CALIBRATION

With the wheel perfectly balanced, apply 100 g first on the outside and then on the inside.

The wheel balancer must measure:

FI=0

FE=100

Weight F.E. = position = 6 o’clock

FI=100

FE=0

Weight F.I. = position = 6 o’clock

Max. permitted tolerance 100 g = 5%.

Содержание 1250

Страница 1: ...SERVICE MANUAL MODELS 1250 1450 1550 1650 1850...

Страница 2: ......

Страница 3: ...Model 1250 Wheel Balancer...

Страница 5: ...M 0495 2 GB...

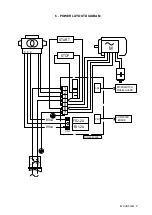

Страница 9: ...M 0495 6 3 GB 5 POWER SUPPLY LAYOUT DIAGRAM 230 V connection...

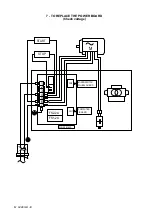

Страница 10: ...M 0495 7 4 GB 6 REPLACING THE POWER BOARD check voltage...

Страница 14: ......

Страница 15: ...Model 1450 Wheel Balancer...

Страница 17: ...M 0492 2 GB...

Страница 30: ......

Страница 31: ...Model 1550 Wheel Balancer...

Страница 33: ...M 0493 2 GB...

Страница 40: ...M 0493 9 5 GB 6 POWER SUPPLY LAYOUT DIAGRAM...

Страница 41: ...M 0493 10 6 GB 7 TO REPLACE POWER BOARD...

Страница 46: ......

Страница 47: ...Model 1650 Vibration Control Diagnostic System...

Страница 49: ...M 0494 2 GB...

Страница 55: ...M 0494 8 5 GB 7 POWER SUPPLY LAYOUT DIAGRAM...

Страница 56: ...M 0494 9 6 GB 8 TO REPLACE POWER BOARD...

Страница 62: ......

Страница 63: ...Model 1850 Wheel Balancer...

Страница 65: ...M 0496 GB 2...

Страница 76: ...SERVICE MANUAL MODELS 1250 1450 1550 1650 1850...