M 0494 -

4

1

�

�

GB

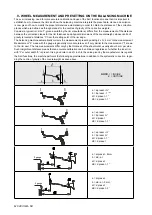

4 - CHECKING AND CALIBRATION OF THE GAUGES

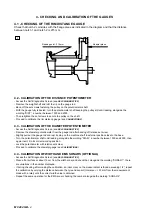

4.1 - CHECKING OF THE RIM DISTANCE GAUGE

Check that notch 2 coincides with the flange plane as indicated in the diagram and that the distance

between notch 1 and notch 2 is 215 mm.

4.2 - CALIBRATION OF THE DISTANCE POTENTIOMETER

- Access the Self-Diagnostics Screen (see

SELF-DIAGNOSTICS

)

- Remove the weight shelf and refit the tip on the gauge rod.

- Back-off the set screws fastening the pulley on the potentiometer shaft.

- With the gauge fully retracted, turn the potentiometer shaft keeping the pulley still until reading, alongside the

wording “DIST”, a number between 1500 and 2000 .

- Then retighten the set screws to secure the pulley on the shaft.

- Proceed to calibrate the rim distance gauge (see

CALIBRATIONS

)

4.3 - CALIBRATION OF THE DIAMETER POTENTIOMETER

- Access the Self-Diagnostics Screen (see

SELF-DIAGNOSTICS

)

- Remove the diameter potentiometer from the gauge rod after backing off relative set screw.

- Slightly pull out the gauge rod and rest its stop on the machine shaft in external position close to the base.

- Turn the potentiometer shaft until reading, alongside the wording “DIAM”, a number between 1500 and 2000, then

again insert it in its correct working position.

- Lock the potentiometer with relative set screw

- Proceed to calibrate the diameter gauge (see

CALIBRATIONS

)

4.4 - CALIBRATION OF WIDTH AND EMS SONARS (OPTIONAL)

- Access the Self-Diagnostics Screen (see

SELF-DIAGNOSTICS

)

- Place a flat surface at about 12 cm from the width sonar and check that, alongside the wording “SONAR 1”, there

are variations in the number displayed.

- If during checking, after making the calibration, an inaccuracy on the measurement is found exceeding 1/2”, repeat

the calibration by varying the distance between the tyre and sensor (tol/- 20 mm from the measurement

made with a ruler) until the correct width value is obtained.

- Repeat the same operation for the EMS sonar checking the number alongside the wording “SONAR 2”.

Reading point : 215 mm

Adapter plane

Содержание 1250

Страница 1: ...SERVICE MANUAL MODELS 1250 1450 1550 1650 1850...

Страница 2: ......

Страница 3: ...Model 1250 Wheel Balancer...

Страница 5: ...M 0495 2 GB...

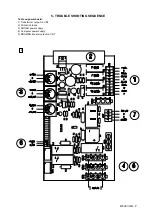

Страница 9: ...M 0495 6 3 GB 5 POWER SUPPLY LAYOUT DIAGRAM 230 V connection...

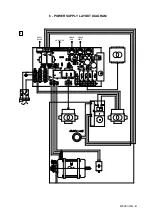

Страница 10: ...M 0495 7 4 GB 6 REPLACING THE POWER BOARD check voltage...

Страница 14: ......

Страница 15: ...Model 1450 Wheel Balancer...

Страница 17: ...M 0492 2 GB...

Страница 30: ......

Страница 31: ...Model 1550 Wheel Balancer...

Страница 33: ...M 0493 2 GB...

Страница 40: ...M 0493 9 5 GB 6 POWER SUPPLY LAYOUT DIAGRAM...

Страница 41: ...M 0493 10 6 GB 7 TO REPLACE POWER BOARD...

Страница 46: ......

Страница 47: ...Model 1650 Vibration Control Diagnostic System...

Страница 49: ...M 0494 2 GB...

Страница 55: ...M 0494 8 5 GB 7 POWER SUPPLY LAYOUT DIAGRAM...

Страница 56: ...M 0494 9 6 GB 8 TO REPLACE POWER BOARD...

Страница 62: ......

Страница 63: ...Model 1850 Wheel Balancer...

Страница 65: ...M 0496 GB 2...

Страница 76: ...SERVICE MANUAL MODELS 1250 1450 1550 1650 1850...