6

User’s guide VUBB

|

1ZSC000562-AAL en

2. Introduction

2.1 General

The on-load tap-changers manufactured by ABB have been

developed over a period of many years to provide maximum

reliability. In most applications, the simple and robust

design provides a service life equal to the service life of the

transformer.

Minimum maintenance is required for trouble-free operation.

Maintenance is normally not required on the parts situated

in the oil of the transformer tank. The only parts requiring

maintenance are the vacuum interrupters (which may

require replacement), the insulating oil and the motor-drive

mechanism.

WARNING

Small amounts of explosive gases are constantly

discharged from the breathing devices (dehydrating

breather or one-way breather). Make sure that no

open fires, hot surfaces or sparks are present in the

immediate surroundings of the breathing devices.

Personnel operating and inspecting the tap-changer

must have good knowledge of the apparatus and be

aware of the risks pointed out in this manual.

Personnel making electrical connections in the motor-

drive mechanism must be certified for such work.

CAUTION

After a pressure relay trip, contact ABB. The tap-

changer housing must be drained and the selector

switch lifted and carefully examined before the

transformer is reenergized.

2.2 Functional description

The on-load tap-changer is a device for changing the tapping

connection of a winding while the transformer is under load.

The main purpose is to maintain a constant voltage out from

the transformer and to compensate for variations in the load

situation. The tap-changer is connected to the transformer

via the tap winding. The main function is tap selection, which

is accomplished by changing the number of turns on the

regulating winding.

Although numerous different circuit solutions are available,

the selected solution has been found to offer the best

combination of technical performance and potential

for economic operation. By using auxiliary contacts in

combination with vacuum interrupters, the contacts are used

for carrying current and the vacuum interrupters are used

for energized switching. With this solution, only two vacuum

interrupters are required per phase.

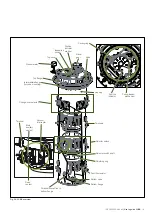

The electrical circuit principle for the VUBB is shown in

Figs. 1-18. The purpose of the operation is to commute the

load from one tap to the other in order to change the voltage.

Depending on in which direction the center shaft is rotating,

two different contact sequences are obtained – either the

main contacts operate first, or in the other direction, the

transition contacts operate first.

The figures on the following pages show the contact

sequence along with the physical position of the interrupter.

Содержание VUBB

Страница 1: ...Vacuum on load tap changers type VUBB User s guide 1ZSC000562 AAL en...

Страница 43: ......