41-748.31B

18

KLF-1 Loss-of-Field Relay

the directional unit need not be cooled

during initial rough adjustment. But, the

directional unit should be cool when final

adjustment is made.

e.

When relay contact closes to the left,

screw out the right-hand plug until spuri-

ous torque is reversed.

f.

When plug adjustment is completed

check to see that there is no closing

torque when relay is energized with 40

amps and voltage terminals 4 and 6

short-circuited.

E. Undervoltage Unit (Lower Unit)

NOTE: The moving contact is in closed position

to the left when de-energized.

1) Contact Gap Adjustments

a.

L.H. (Normally Closed) Contact Adjustment

With the moving contact arm in the closed

position, against left-hand side of bridge,

screw the left-hand contact in to just touch

the moving contact (use neon light for indica-

tion) and then continue for one more com-

plete turn.

b.

R.H. (Normally Open) Contact Adjustment

With moving contact arm against the left-

hand stationary contact, screw the right-hand

stationary contact until it just touches the

moving contact. Then back the right-hand

contact out two-thirds of one turn to give

0.020 inch contact gap.

2)

Sensitivity Adjustment

a.

Apply voltage to terminals 4 & 7. Connect

the brush lead of the adjustable resistor,

R

V

, that is located in the rear (second from

the bottom) to maximum. Adjust the spring

so that contacts make (to the left) at 70

volts. The contact should open when unit

is energized with 71 or more volts.

b.

Relay is set for 90 volts. This is accom-

plished by lowering resistance value of R

V

until contacts make at 90 volts and open

when unit is energized with 91 or more

volts. The spring should not be used for

this setting.

F. Indicating Contactor Switch (ICS)

Initially adjust unit on the pedestal so that arma-

ture fingers do not touch the yoke in the reset

position. (Viewed from top of switch between

cover and frame.) This can be done by loosening

the mounting screw in the molded pedestal and

moving the ICS in the downward position.

1. Contact Wipe – Adjust the stationary contact

so that both stationary contacts make with

the moving contacts simultaneously and

wipe 1/64” to 3/64” when the armature is

against the core.

2.

Target – Manually raise the moving contacts

and check to see that the target drops at the

same time as the contacts make or up to

1/16” ahead. The cover may be removed and

the tab holding the target reformed slightly if

necessary. However, care should be exer-

cised so that the target will not drop with a

slight jar.

3.

Pickup – The unit should pickup at 98% rat-

ing and not pickup at 85% of rating. If neces-

sary, the cover leaf springs may be adjusted.

To lower the pickup current use a tweezer or

similar tool and squeeze each leaf spring

approximately equal by applying the tweezer

between the leaf spring and the front surface

of the cover at the bottom of the lower win-

dow.

4. If the pickup is low, the front cover must be

removed and the leaf spring bent outward

equally.

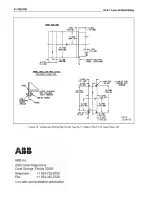

G. Solid State Time Delay Circuit

Refer to Figure 14 (page 27) for the following

test:

a.

Connect a jumper between the “D” contacts

(top unit) and connect a switch between the

D-contact and relay terminal 10.

b.

Connect a scope probe, common and exter-

nal trigger to relay terminals 1, 3 and contact

“D” respectively.

c.

Connect a rated dc power supply between

relay terminals 10 (+) and 3 (-).

d.

Turn on the dc power supply and then turn

on the switch. The voltage at terminal 1