I.L. 41-661.2A

the breaker immediately trip again, contacts Y5

and X8 will be open to prevent premature ener-

gization of the breaker close circuit.

COMPLETE OPERATING SEQUENCE

Fault-Trip -Immediate Reclosure

0

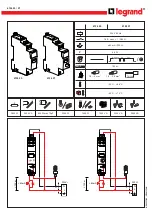

Refer to Fig. 5. With the timing drum in the

“Start” position, a #3 cam spring will be holding

contact #3 closed. The breaker switch contacts

52b and 52bb close, energizing the motor 79M

through contact #I, and the drum begins to ro-

tate. At the same time the coil of the contactor

unit, 79X, is energized through drum contact #3,

and contact YS. When the breaker latch checking

switch, 52LC, closes, the breaker control relay

52X is immediately energized through the pre-

closed contacts YS and 3. This in turn energizes

the closing coil of the breaker, 52C. Simulta-

neously, contactor unit, 79X, seals in through its

contact X8, while its other contact, X9, energizes

the coil of solenoid unit 79Y to open contacts

YS and Y 13 and close contact Y7. As the circuit

breaker closes, the breaker auxiliary switches 52b

and 52bb open, and 52a closes. Opening 52bb

de-energizes 79X and 79Y. The latter then resets

against its latch, thus leaving contacts YS and

Y 13 open and contact Y7 closed until the latch

is released. Before the latch is released, the drum-

operated contact, 14, will be opened and will

remain open until the drum returns to the “Start”

position.

Preparing for Second Reclosure

The drum continues to rotate. When the

breaker trips the second time, no immediate

operation occurs. At about one second, #2 cam

contact closes to set up the motor circuit when

the breaker is subsequently reclosed. At about

the three second drum position contact #3

opens. At about 6 seconds, the Y unit latch is

released by the #S cam, resetting the Y unit. The

relay is now ready for another reclosure as soon

as contact #3 is closed by the #3 cam spring. The

drum will continue to rotate, since the motor is

energized through S2b and #l contacts.

Second and Third Reelosures

At 15 and 45 seconds the #3 contact closes to

reclose the breaker. After each reclose, the Y unit

is unlatched by the action of cam #S.

6

Lockout

When the drum reaches the lockout position,

the motor is de-energized, since cam contact #I

opens (assuming the breaker is open). The breaker

must then be closed by the control switch. If

the breaker then remains closed the drum will

rotate to the “Start” position, where the motor is

de-energized by the #2 cam contact.

CHARACTERISTICS

The standard rating for the relay is:

Motor . . 120/240 V, 60 hertz

X and Y Units.

. . .

120/24OV, 60 hertz

or 481125 Vdc

Drum Speeds.,

.

.

. . . . . .

6 0 - 9 0 - 1 8 0 - 3 6 0

Sec./Rev.

When the motor is to be operated at 240 volts

a resistor in the bottom right side is connected in

series with the motor coil. Relays are available for

operation on SO hertz. X and Y units can be sup-

plied for a minimum rating of 24 volts d-c, or

with a 250 volt rating.

BURDEN DATA

The maximum burdens for the various units

of the standard RCL relay when energized from a

120 V, 60 cycle supply are listed below:

Contactor Unit (Device 79X)

Open position

. . . .

49 VA

C l o s e d p o s i t i o n

.

33 VA

Solenoid Unit (Device 79Y)

O p e n p o s i t i o n

.

15 1 VA

Closed position

. . . .

84 VA

Synchronous Motor (Device 79M).

. .

8.5 VA

The burdens of the X and Y units occur only

momentarily during the reclosing cycle but the

motor is energized throughout the .reclosing cycle.

The X and Y units can be energized for a 1 min-

ute period and the motor for a 15 minute period

without injury.

SETTINGS

No

settings are necessary unless factory settings

do not meet the application requirements. The

factory settings are for three reclosures - imme-

diate, 15 and 45 seconds, with a drum revolu-