11

5.

Attach a properly sized length of Selkirk Metalbestos model

PS or model G venting to the exhaust vent adapter using the

inner vee bands, see Figures 7 and 7B on page 10.

6.

Fill the grooves in both inner vee bands with high-temp

silicone sealant, Dow Corning 736 or equivalent.

7.

Position the inner vee bands around the inner pipe flanges

and tighten the screws securing the bands.

8.

Align the outer channel band with the outer pipe grooves

and tighten the screws securing the bands.

9.

Repeat steps 6-8 for each successive pipe length until the

venting reaches the heater.

10. Follow the manufacturer’s instructions for proper support

and guide spacing for horizontal runs of pipe, see Table 6.

TABLE 6.

Vent Diameter

S

F

8” - BTPV -540A, 650A & 740A

15’ 3”

7’ 6”

S = Maximum spacing between two guides or a support

and a guide in either a vertical or horizontal direction.

F = Maximum height above a guide or support for free

standing system above a roof or parapet wall.

11. Use an expansion joint between any two fixed points in the

exhaust venting system wherever the expansion may exceed

1/4”. Selkirk Metalbestos model PS and model G venting

will expand by one inch per 100°F in gas temperature per

100 feet of vent length. The expansion can be calculated by

the following formula:

Expansion,

Vent length between

5

Inches

two fixed points, feet 100

If the expansion calculated is greater than 1/4”, an expansion

joint must be used between the two fixed points.

12. Attach the flue reducer included in the exhaust vent hood

package to the flue collar on the heater.

13. Attach the flue reducer to the vent system using a seal ring.

Attach this ring to the venting using the inner vee bands as

outlined in Steps 5-7.

14. Attach 8” air-intake connector to intake vent hood collar. It

may be necessary to use a slip-slip coupling to fit the pipe

to the intake vent hood.

15. Attach 8” air-intake connector back to the 6” burner air inlet

with 8” x 6” reducer. Prime and cement each joint to assure

gas-tight construction.

16. Seal all joints at the vent hoods with silicone sealant. Also

seal the joints at the flue collar and air inlet adapter. Joint on

the exhaust side must be sealed with high-temp silicone

sealant, Dow Corning 736 or equivalent.

WARNING

PRIMERS AND CEMENTS ARE EXTREMELY FLAMMABLE, AND

MUST NOT BE STORED OR USED NEAR HEAT OR OPEN FLAME.

ALLOW ADEQUATE CURING TIME BEFORE OPERATING HEATER.

DRAIN VALVE AND ACCESS PANELS

The heaters are equipped with a 3/4” NPT drain valves mounted

above and to the left of the burner.

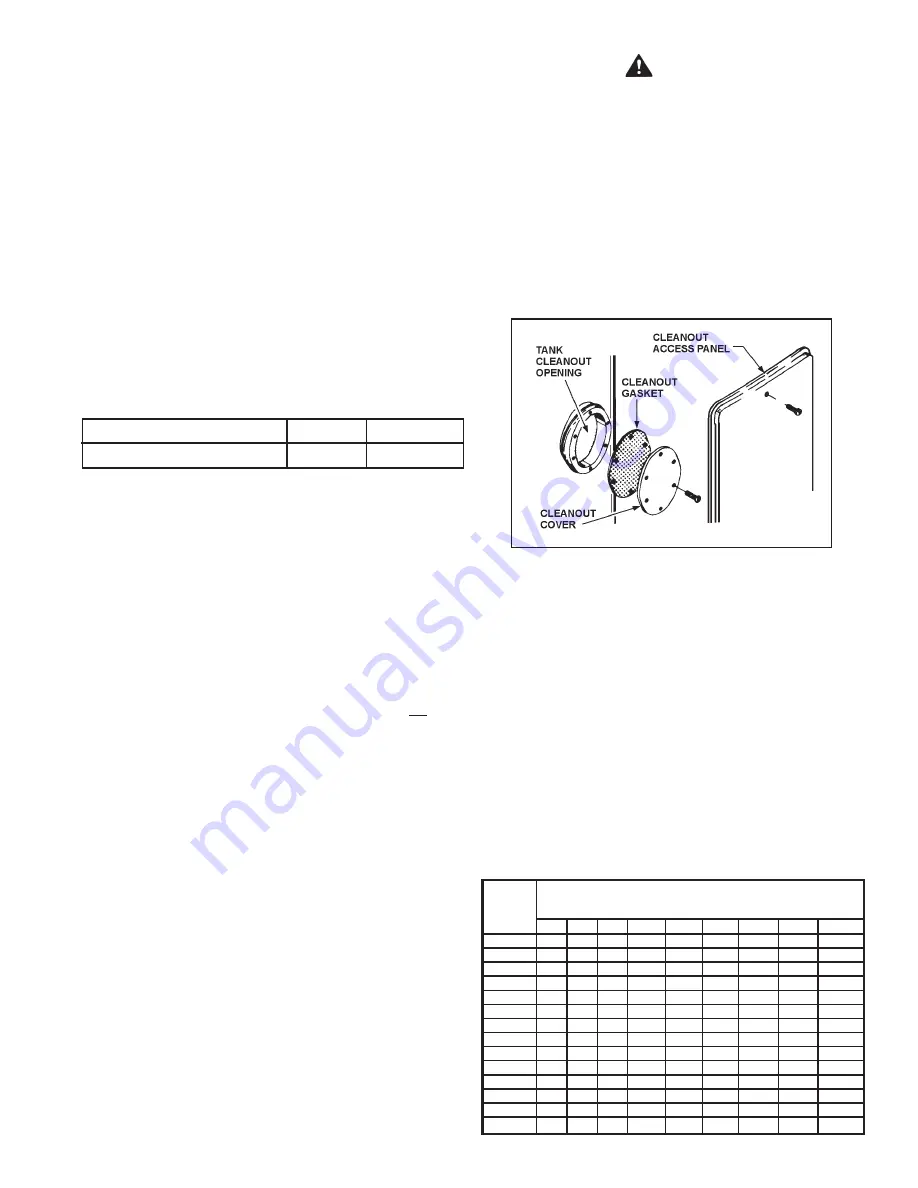

An access panel is located above and to the right of the burner,

see Figure 8. This panel covers the cleanout opening in the tank

which is sealed by a gasket and cover. Another cleanout access

panel is located towards the back of the heater.

FIGURE 8.

GAS PIPING

Contact your local gas service company to ensure that adequate

gas service is available and to review applicable installation

codes for your area.

Size the main gas line in accordance with Table 9 and 9A.

Minimum required gas supply pipe size is 1 1/4”. The figures

shown are for straight lengths of pipe at 0.5 in. w.c. pressure

drop, which is considered normal for low pressure systems.

Note that fittings such as elbows and tees will add to the pipe

pressure drop.

TABLE 9

MAXIMUM CAPACITY OF PIPE IN CUBIC FEET OF GAS PER HOUR

(Based upon a Pressure Drop of 0.5 inch Water Column

and 0.5 Specific Gravity Gas and max. gas press. of .5 psig)

LENGTH

IN

Nominal Iron Pipe Sizes, Inches

FEET

1/2"

3/4"

1"

1 1/4" 1 1/2"

2"

2 1/2"

3"

4"

10

175

360

680

1400

2100

3960

6300

11000

23000

20

120

250

485

950

1460

2750

4360

7700

15800

30

97

200

375

770

1180

2200

3520

6250

12800

40

82

170

320

660

990

1900

3000

5300

10900

50

73

151

285

580

900

1680

2650

4750

9700

60

66

138

260

530

810

1520

2400

4300

8800

70

61

125

240

490

750

1400

2250

3900

8100

80

57

118

220

460

690

1300

2050

3700

7500

90

53

110

205

430

650

1220

1950

3450

7200

100

50

103

195

400

620

1150

1850

3250

6700

125

44

93

175

360

550

1020

1650

2950

6000

150

40

84

160

325

500

950

1500

2650

5500

175

37

77

145

300

460

850

1370

2450

5000

200

35

72

135

280

430

800

1280

2280

4600

=

x

Содержание Conservationist BTPV 650A

Страница 20: ...20 FIGURE 11...

Страница 21: ...21 FIGURE 12...

Страница 25: ...25 PREMIX LOW NOx BURNER EXPLODED VIEW FOR BTP MODELS FIGURE 13...

Страница 26: ...26 PREMIX LOW NOx BURNER EXPLODED VIEW FOR BTPV MODELS FIGURE 14...

Страница 34: ...34 NOTES...

Страница 35: ...35 NOTES...