18

19

ENGLISH

ENGLISH

TROUBLESHOOTING

Use the table below to help identify possible causes and corrective action for problems you may

experience.

There are no user serviceable parts inside the TR-300 PAPR Assembly. The motor

blower unit should not be opened to attempt repair or for any other reason.

Consult the

TR-300

Trouble Shooting Guide

or Contact 3M Technical Service to help identify additional possible causes and

corrective actions for other problems you may experience.

Fault

Possible Cause(s)

Possible Solution(s)

All LEDs fl ash and

alarm

1) System software malfunction.

1) To clear the alarm, power down

motor/blower unit and remove the

battery pack. Allow unit to sit for

several minutes before reconnecting

battery pack and turning the unit

back on. If unit does not reset,

contact 3M Technical Service.

Low airfl ow alarm

(audible and/or

LED fl ashing).

1) Breathing tube is blocked.

2) Air Inlet is covered.

3) Filter is fully loaded with

particles.

1) Check & remove blockage or

obstruction.

2) Check air fi lter & remove obstruction.

3) Change HE fi lter and prefi lter or spark

arrest or/prefi lter.

Bottom bar of

battery pack

indicator fl ashes;

battery alarm

sounds.

1) Low battery voltage.

2) Battery pack not properly

installed.

3) Battery pack past service life.

4) Battery pack temperature too

hot > 140ºF (> 60ºC).

1) Recharge the battery pack.

2) Remove and reinstall battery pack.

3) Install a new, fully-charged TR-300

battery pack.

4) Bring to cool environment, allow

battery pack to cool.

No airfl ow, no

alarm(s).

1) Battery pack contact on battery

pack is damaged.

2) Battery pack is completely

discharged (no charge).

3) Damaged circuit board.

4) Damaged motor.

1) Check that the battery pack contact

is not bent or broken.

2) Fully charge the battery pack.

3) Contact 3M Technical Service.

4) Contact 3M Technical Service.

Low airfl ow as

indicated by fl ow

meter but no

alarm(s).

1) Damaged circuit board.

2) Damaged motor.

3) Flow indicator not held in

vertical position.

1) Contact 3M Technical Service.

2) Contact 3M Technical Service.

3) Ensure fl ow indicator is held in

vertical position during inspection.

User detects

odor or taste of

contaminants or

feels eye or throat

irritation.

1) Incorrect respirator for

application and /or environment.

1) Consult on-site industrial hygienist or

safety director.

Battery pack’s

charge lasts less

than expected.

1) Inadequate charging.

2) HE fi lter is loaded with particles,

making the motor run harder.

3) Battery pack reaching end of

service life.

1) Ensure battery pack is fully charged.

2) Check the low fl ow indicator. Replace

the HE fi lter & prefi lter or clean the

spark arrestor.

3) Replace battery pack.

The motor runs

“faster than

normal”.

1) The HE fi lter is loaded with

particles.

1) Check the low fl ow indicator. Replace

the HE fi lter & prefi lter and clean the

spark arrestor.

2) Let the unit run for 2 minutes so

it can automatically adjust to the

new fi lter or changes to the fi lter

confi guration.

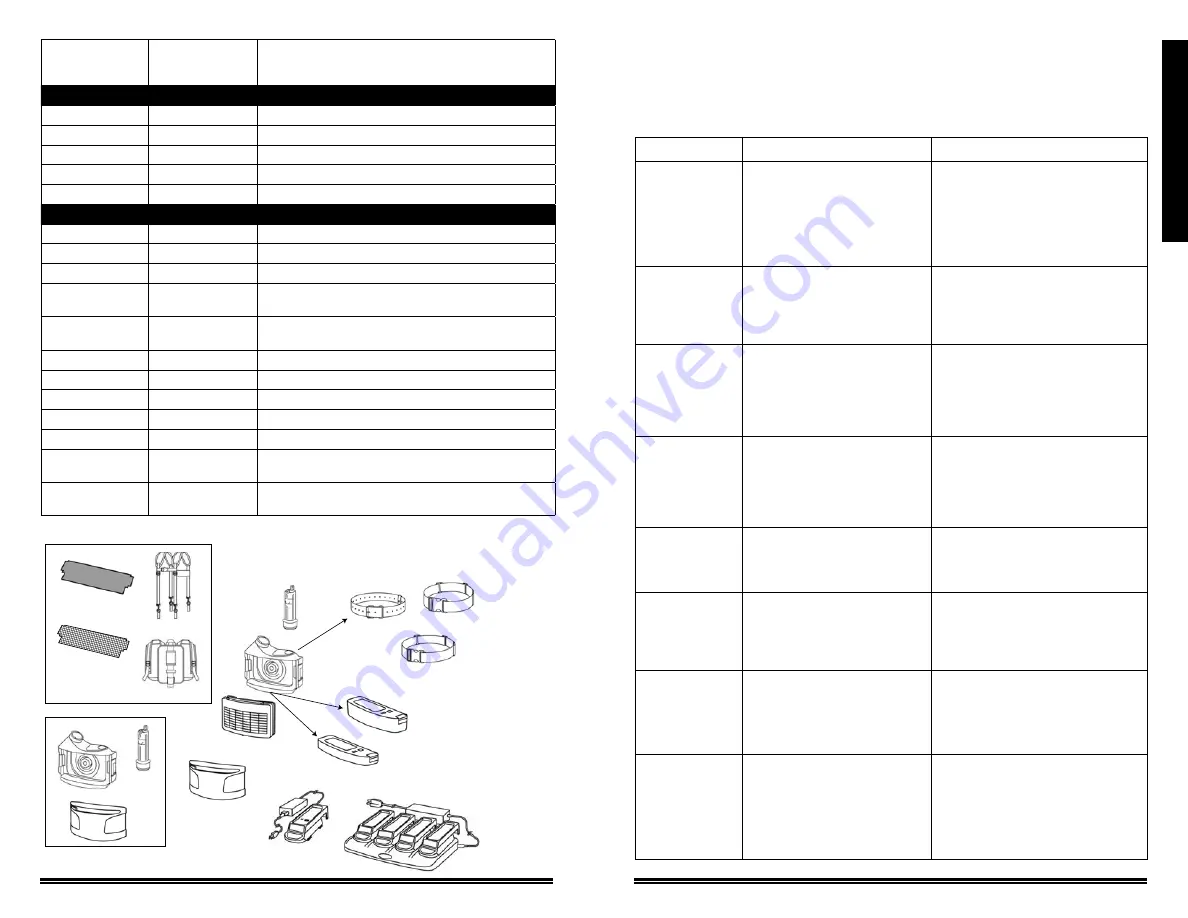

Versafl o™

TR-300

PAPR Part #

Speedglas™

TR-300-SG*

PAPR Part #

Description

Filters

NA

TR-3710N-SG-2

HE Filter (2 per case)

TR-3710N-5

TR-3710N-SG-5

HE Filter (5 per case)

TR-3710N-40

TR-3710N-SG-40

HE Filter (40 per case)

NA

TR-3810N-SG-2

HE/Nuisance OV Filter (2 per case)

TR-3810-5

TR-3810N-SG-5

HE/Nuisance OV Filter (5 per case)

Replacement Parts & Additional Accessories

TR-301N

TR-301N

Replacement Blower for TR-300 PAPR

TR-370

TR-370-SG

Filter Cover

TR-970

TR-970

Airfl ow Indication

TR-3600

NA

Prefi lter – for use with selected 3M™ hoods and

headtops.

TR-362

TR-362-SG

Spark Arrestor/Prefi lter – for use with selected 3M™

headgear and Speedglas™ welding headgear

TR-329

TR-329

Suspenders

TR-941N

TR-941N

Replacement Power Supply, Single Station

TR-944N

TR-944N

Replacement Power Supply and base, 4-Station

BT-922

NA

Breathing Tube Cover

BT-926

BT-926

High Temperature Breathing Tube Cover

NA

TR-3715-SG

High Effi ciency Starter Kit #1 (2 HE fi lters, 2 spark

arrestor/prefi lter)

NA

TR-3815-SG

High Effi ciency Starter Kit #2 (2 HE/Nuisance OV fi lters,

spark arrestor/prefi lter)

*

Catalog number only. Approved under the 3M™ Versafl o™ model number.

TR-326

TR-970

TR-370

TR-302N

TR-362

TR-3600

TR-329

BPK-01

TR-330

TR-341N

TR-344N

TR-332

TR-3710N,

TR-3810N

TR-325

TR-327

TR-301N

netzerotools.com

netzerotools.com

Содержание Versaflo TR-300-SG

Страница 44: ...84 84 netzerotools com netzerotools com...