EO Abator Operation and Installation Manual

10

Customer

Checklist

29. Has the safety vent line been checked to ensure that it is gas

tight?

Yes □

No □

Exhaust System – Arrangement 1

30. Is there a negative pressure in the duct?

Yes □

No □

Exhaust System – Arrangement 2

31. Is the measured air flow in the 152 mm (6 inch) duct between

5.66-7.08 m

3

/min (200-250 ft

3

/min)?

Yes □

No □

32. Has an insulated duct been connected to the EO Abator outlet?

Yes □

No □

33. Is the insulated duct dedicated solely to the EO Abator system

outlet all the way to its outside termination?

Yes □

No □

34. Is the exhaust system leak tight?

Yes □

No □

35. Is the back pressure in the exhaust duct with the “abator

ready” light illuminated, less than 7.62 mm (0.3 in.) H

2

0?

Yes □

No □

36. Is the ductwork material impervious to EO?

Yes □

No □

37. What is the diameter in mm (in.) of the duct?

mm (in.)

38. What is the distance in M (ft.) between the outside exhaust

termination and any sources of building air intake?

M (ft.)

General

39. Did you obtain all state and local regulations concerning EO

emissions?

Yes □

No □

Purchaser’s Responsibility

Only health care professionals, or other appropriately trained personnel in health care and industrial areas, should use

this equipment. It is a violation of federal law to use this product in a manner inconsistent with its labeling. Injury to

persons or property can result unless the operating instructions are followed carefully.

It is the purchaser’s responsibility to provide the necessary machine service requirements to the area where the sterilizer

and EO Abator system are to be installed. These services include electricity, EO inlet line, safety vent line, and a

dedicated exhaust system.

Because of varying local codes and labor policies, it is also the responsibility of the purchaser to locate the EO Abator

system in its permanent location and to connect the services to the machine. It is the purchaser’s responsibility to ensure

that local requirements are met.

EO Abator Efficiency Testing

During the installation and start up process performed by 3M, the EO Abator is tested for electronic function. It is the

recommendation of 3M Company that the EO Abator be tested for efficiency on a regular basis as required by local,

state or federal regulations by using a gas chromatography method. This method of testing is accepted by most local

and state agencies and will provide an efficiency baseline of performance. If independent certification of efficiency

is required by state or local authorities or if it is desired by your facility, 3M Company recommends that your facility

contact a test lab or company certified by state or local agency. 3M does not perform efficiency testing of the Abator.

Return used catalytic cells to 3M Health Care Service Center for proper handling.

Содержание 50AN

Страница 1: ...3 Operation and Installation Manual Models 50AN 50AE 50AJ EO Abator ...

Страница 20: ...EO Abator Operation and Installation Manual 19 Figure 3 For 5XL 8XL and GS Series Sterilizers D Connector ...

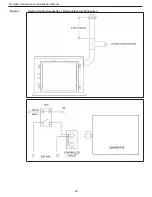

Страница 22: ...EO Abator Operation and Installation Manual 21 Figure 5 Clearances Required ...