Reviews:

No comments

Related manuals for PNOZ X9

STW1000V2

Brand: ZIEHL Pages: 6

SNO 2004K

Brand: Wieland Pages: 16

BIS-412M 24V

Brand: F&F Pages: 7

MFAC 14

Brand: GE Pages: 25

MLJ

Brand: GE Pages: 42

MDP

Brand: GE Pages: 68

MOV 2000

Brand: GE Pages: 78

MOTOR MANAGEMENT RELAY 469

Brand: GE Pages: 311

MiCOM P40 Agile P14D

Brand: GE Pages: 12

SEL-487V

Brand: Schweitzer Engineering Laboratories Pages: 32

Soft Touch Relay Bypass

Brand: MAS Pages: 4

ELD V2

Brand: Ampcontrol Pages: 19

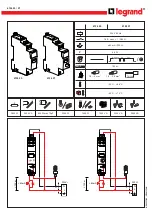

CX3

Brand: LEGRAND Pages: 2

001DC009AC

Brand: CAME Pages: 12

HR6S Series

Brand: IDEC Pages: 36

EDR-5000

Brand: Eaton Pages: 1017

ZE/XTOM Series

Brand: Eaton Pages: 64

ESR5-NZ-21-24VAC-DC

Brand: Eaton Pages: 19