IS950XLTDABF (REV. D 5/18)

ZURN WILKINS

1747 Commerce Way, Paso Robles, CA 93446 Phone:855-663-9876 Fax:805-238-5766

SPECIFICATIONS

Maximum working water pressure:

175 PSI

Hydrostatic test pressure:

350 PSI

Maximum working water temperature:

180°F

End connections:

Threaded ANSI B1.20.1

PROBLEM

1. LEAKING CHECK VALVES

2. LOW OR NO FLOW

CORRECTIVE ACTION

1. Clean seat and seal ring area

2. Replace seat

3. Replace seat o-ring

1. Verify flow direction arrow

2. Turn handles counterclockwise

3. Attach pressure gauge to test cock

#1 and verify pressure

POSSIBLE CAUSES

1. Debris on seat or seal ring

2. Damaged seat

3. Damaged seat o-ring

1. Device installed backwards

2. Shut-off valves or valve upstream

may not be fully open

3. Low supply pressure

Proper performance is dependent upon licensed, qualified personnel performing regular, periodic testing according

to ZURN WILKINS’ specifications and prevailing governmental & industry standards and codes and upon following

these installation instructions. Failure to do so releases ZURN WILKINS of any liability that it might otherwise have

with respect to that device. Such failure could also result in an improperly functioning device.

⃟

Rated Flow (Established by approval agencies)

Troubleshooting

Performance Characteristics

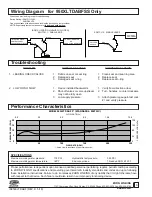

BLACK

(SWITCH POSITION VALVE FULL OPEN)

SWITCH 1: DUAL LEADS

RED

WHITE

LISTED FIRE ALARM

CONTROL PANEL

SUPERVISORY CIRCUIT

NC

COM

NO

TO NEXT INDICATOR

OR

END OF LINE RESISTOR

Green Lead provided is ground for switch housing

Switch Rating: 10AMP/ 115 VAC

.5AMP/28 VDC

Cap unused leads with wire nuts and tuck inside junction box (not provided)

NOTE: Supervisory tamper switches are for

indoor and outdoor use.

SWITCH 2: SINGLE LEADS

AUXILIARY

EQUIPMENT

ORANGE

YELLOW

BLUE

COM

NC

NO

VOLTAGE

SOURCE

Wiring Diagram for 950XLTDABFSS Only

4

®

www.zurn.com

0

34

69

103

138

0.0

3.2

6.3

9.5

12.6

15.8

0

5

10

15

20

0

50

100

150

200

250

PR

ESSU

R

E

LO

SS

(k

Pa

)

FLOW RATE (l/s)

P

R

E

SSU

R

E

L

O

SS

(P

SI

G

)

FLOW RATE (GPM)

MODEL 950XLTDABF 2" (STANDARD & METRIC)