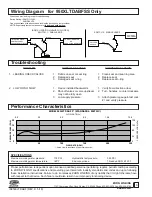

SCREW

SEAL RING

RETAINER

SEAL RING

POPPET

CHECK SEAT

SEAT O-RING

ZURN WILKINS

1747 Commerce Way, Paso Robles, CA 93446 Phone:855-663-9876 Fax:805-238-5766

POPPET ASSEMBLY

#1 SPRING

#2 SPRING

POPPET ASSEMBLY

SCREW

SEAL RING

SEAL RETAINER

POPPET

#2 TEST COCK

#3 TEST COCK

#4 TEST COCK

COVER O-RING

NO. 1 CHECK

VALVE COVER

COVER O-RING

NO. 2 CHECK

VALVE COVER

#1 TEST COCK

FIGURE 3

3

CHECK ASSEMBLY

FIGURE 1

FIGURE 2

Maintenance Instructions

All Model 950XLTDABF Double Check Detector Backflow

Preventers must be inspected and maintained by licensed

personnel at least once a year or more frequently as

specified by local codes. Replacement of worn or damaged

parts must only be made with genuine "ZURN WILKINS"

parts.

GENERAL MAINTENANCE

1. Clean all parts thoroughly with water after disassembly.

2. Carefully inspect rubber seal rings and o-rings for damage.

3. Test unit after reassembly for proper operation (refer to

"TESTING PROCEDURES").

SERVICING CHECK VALVES

1. Close inlet and outlet shut-off valves.

2. Open No.2, No.3 and No.4 test cocks to release pres-

sure from valve.

3. Unscrew check valve cover using appropriate sized

wrench.

CAUTION:

COVER IS SPRING LOADED!

To avoid injury, hold cover down firmly with one hand

while unscrewing.

4. Remove cover, spring and poppet assembly.

5. Inspect the rubber seal ring for cuts or embedded

debris.

6. To remove seal ring, remove screw and seal retainer.

7. If the reverse side of the seal ring is unused, it is

possible to invert the seal ring. This would be consid-

ered a temporary solution to fixing a fouled check and

should be replaced with a new seal ring as soon as

possible.

8. Inspect the valve cavity and seating area. Remove

any debris.

9. If necessary, unscrew seat from body and replace with

new seat and lightly greased o-ring (For seat removal

assistance, contact factory).

10. Reverse the above procedures to reinstall check

valve assemblies and access cover, making sure

the 3 test cocks remain open.

®

www.zurn.com