11

1x

Sensor position out of working range

2x

Working range incorrectly set

3x

Off the tolerance level of magnetic field

4x

Wrong parameters in EEPROM

5x

Wrong parameters in RAM

4. Calibration of currents 4 mA and 20 mA.

On switching-on the power supply, keep the push-buttons “4” and “20” depressed and release them after a sin-

gle blink of LED. In this way the option menu 4.1 Calibration of current 4 mA is entered.

4.1. Calibration of current 4 mA

Connect the ammeter to testing terminals. Press the push-button “20”. Keep depressed the push-button to evoke

the auto-repeat of current decrease. Release the push-button to make record of the present value.

4.2. Calibration of current 20 mA

Connect the ammeter to testing terminals. Press the push-button “4”. Keep depressed the push-button to evoke

the auto-repeat of current increase. Release the push-button to make record of the present value.

4.3. Switching-over between option of calibration 4 mA and 20 mA

Entry of option of calibration 4 mA:

Press the push-button “4”, then the push-button “20” and keep them depressed until LED blinks.

Entry of option of calibration 20 mA:

Press the push-button “20”, then the push-button “4” and keep them depressed until LED blinks.

5. Record of standard parameters

On switching-on the power supply, keep the push-buttons “4” and “20” depressed and release them after

a double blink of LED.

ATTENTION! With this record, the transmitter calibration is also overwritten and, therefore, it must be repeated!!

Parameter setting

ACTUATOR ASSEMBLY AND PUTTING INTO OPERATION

After unpacking the actuator, this should be inspected for possible visible signs of damage that could happen

during transportation or storage. If no visible damages are detected, the actuator can be connected to external con-

trol and power circuits. Using a short-time switching-on of the actuator in its intermediate position of the working

stroke, make sure that the actuator output shaft rotates in a correct direction. This can be verified by pressing the le-

ver of the particular micro-switch (end-limit position or torque switch, depending on the way of controlling the actua-

tor) using an insulation rod with the actuator operating in certain direction. By pressing the lever of the torque switch

MZ or end-limit switch PZ with the output shaft rotating in the Close direction, the actuator should stop. With the

output shaft rotating in the Open direction, the levers MO and PO should be pressed. If the actuator does not stop by

the mentioned pressing but does stop by pressing the levers MO and PO with rotation in the Close direction or MZ

and PZ with rotation in the Open direction (i.e. the micro-switch levers switch off the electric motor with rotation in

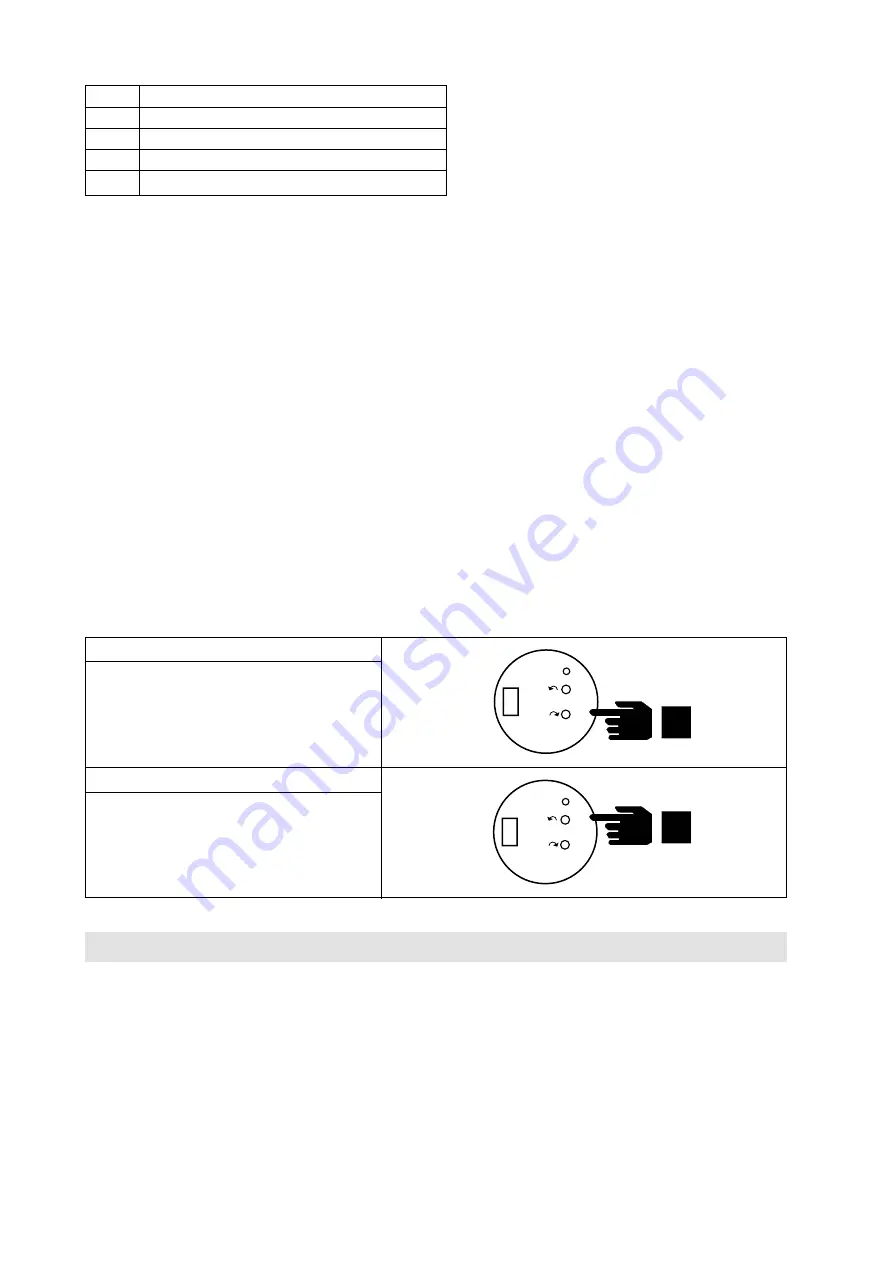

Position “4 mA“

Set the actuator to required position (usually

Closed) and keep the push-button 4 depressed

until LED blinks.

Position “20 mA“

Set the actuator to a required position (usually

Open) and keep the push-button 20 depressed

until LED blinks.

20

4

- L

+ L

- U

+ U

1

DCPT

EHL elektronika

v.č. 000106

20

4

- L

+ L

- U

+ U

1

DCPT

EHL elektronika

v.č. 000106

2 s

2 s