4

© Copyright 2018 Zoeller

®

Co. All rights reserved.

General Information

GRINDER PUMP DESCRIPTION

1. Pumps are constructed of class 30 cast iron protected with powder

coated epoxy for long life when pumping sewage in submersible

applications. The cutter assembly is comprised of stainless steel

components hardened to a value of 55-60 on the Rockwell C scale;

a star shaped cutter and a precision ground flat disk. Cutting action

takes place with the rotation of the star cutter at 3450 RPM against

the stationary cutter plate (see page 11).

2. The cutter mechanism on the model 7011 is bidirectional, enabling

it to cut in either direction. A control panel with the reversing feature

will alternate the pump’s rotational direction with each duty cycle. The

cutter mechanism on the model 7012 & 7013 is single directional.

3. Pump motors are available in single and three phase design. Single

phase motors require a Zoeller approved starting relay, starting

capacitor and a run capacitor, which are mounted in a control panel

(ref. page 8).

4. The 7011, 7012 and 7013 Grinder Pumps are dual seal and have seal

leak probes. Single phase units have an internal thermal overload.

Three phase pumps have a thermal sensor.

5. Three phase pumps require overload protection in the control

panel.

6. A Grinder Pump is an intermittent duty pump designed for pumping

sanitary sewage. It is not a dewatering or trash pump.

FIELD ASSEMBLED INSTALLATION

1. Installation and piping instructions are included with the control panel,

rail system and basin instructions. If pump is being retrofitted to an

existing rail system, accessory parts may be required. Consult the

factory and advise make and model of rail system being used.

2. Refer to the appropriate Indoor/Outdoor prepackaged instructions

on pages 6-9 for more information on system installation.

3. All electrical connections including pump to control box and power

supply to control panels must comply with the “National Electrical

Code” and applicable local codes. Conduit and panel enclosure

openings must have a gas and watertight seal. Installation of

electrical panels, conduit and connections should be made by a

qualified licensed electrician. A UL Listed potting kit, P/N 10-2350,

is available from Zoeller Company.

4. A properly sized disconnect switch, supplied by others, shall be

installed on the service side of the pump and control panel.

5. When installing a pump with a check valve, or a rail system with

a check valve, you must give the pump case time to fill to help

prevent air lock when lowering the unit into the liquid. The pump

case has an air vent located behind the discharge. This air vent is

across the pump housing mounting surface and must be cleaned

before each reinstall. An extra air vent hole (3/16") may be drilled

in discharge pipe below the check valve to help prevent air lock.

This drilled hole must be cleaned before each reinstall. After the

pump is installed, run the unit submerged to assure the pump case

is filled (Water should come out of 3/16" diameter hole).

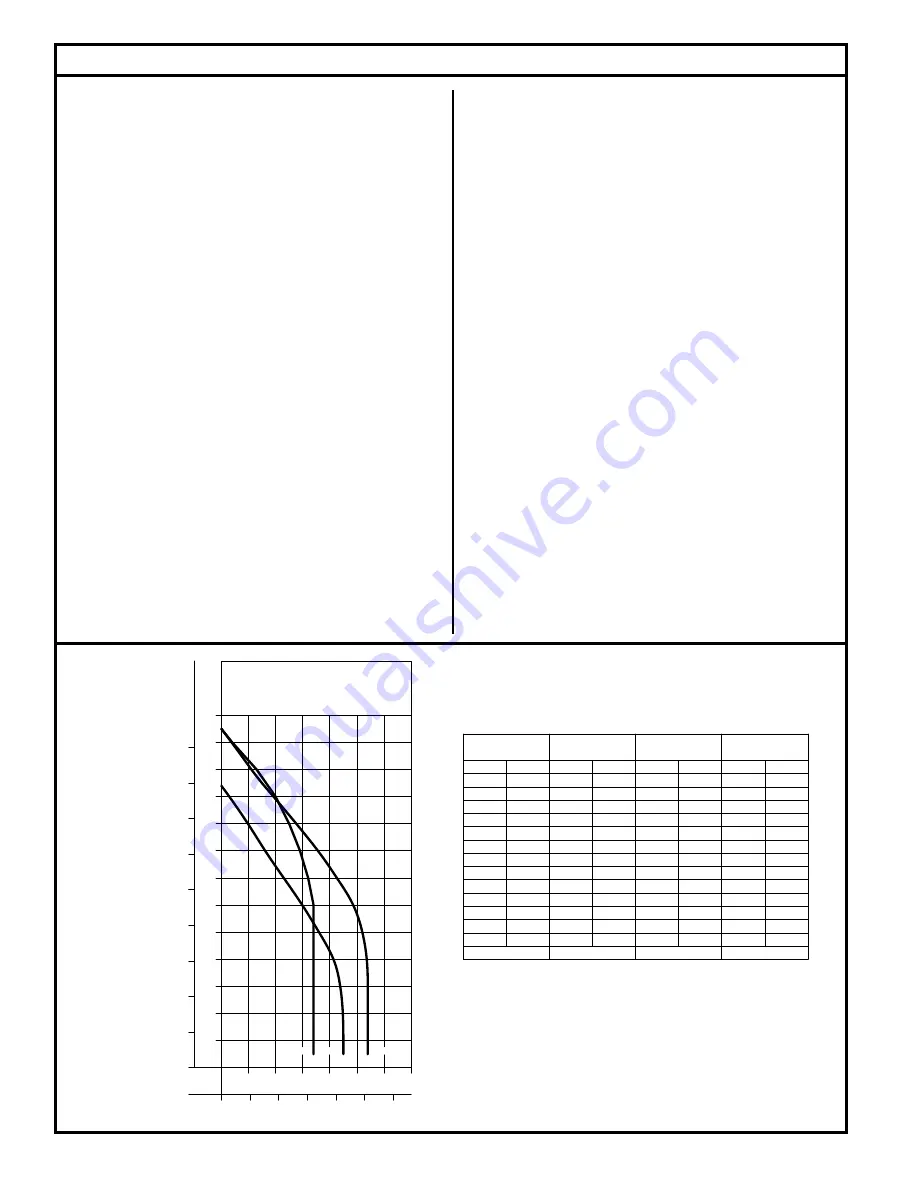

FIGURE 1.

016532

HEAD CAPACITY CURVE

MODEL 7011/7012/7013

0

40

80

120

160

200

240

70

60

50

40

30

20

10

0

10

4

8

12

16

20

130

70

60

50

40

30

20

FLOW PER MINUTE

GALLONS

LITERS

TO

TAL D

YNAMIC HEAD

80

90

28

24

METERS

FEET

100

110

120

32

36

7011

7013

7012

TOTAL DYNAMIC HEAD/FLOW

PER MINUTE

SEWAGE

MODEL

Feet

Shut-off Head:

7011

Meters

Gal.

Liters

5

10

20

30

9.1

6.1

3.0

1.5

44

45

167

170

104 ft (31.7 m)

60

50

40

90

80

70

110

100

120

12.2

15.2

18.3

21.3

24.4

27.4

30.5

33.5

36.6

42

36

30

114

136

159

23

16

10

38

61

87

3

--

--

--

--

11

125 ft (38.1 m)

7013

Gal.

Liters

45

170

45

170

125 ft (38.1 m)

95

25

13

4

20

76

49

15

34

32

29

34

34

34

34

129

121

110

129

129

129

129

7012

Gal.

34

34

129

129

Liters

52

49

185

197

43

36

28

106

136

163

19

11

4

15

42

72

54

204

54

204

54

204

54

204

54

204