p. 12/69

3.

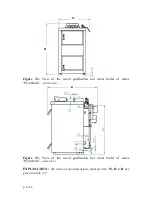

Description of the wood gasification hot water boiler

of series “Pyrotherm

”.

The heat exchanger of the hot water boiler of series “Pyrotherm” complies

with the acting requirements for such kind of units, defined in operating norm :

EN 303-5/2000 – „Heating boilers for solid fuels, hand and automatically fired,

nominal heat output up to 300 kW. Terminology, requirements, testing and

marking”.

The hot water boiler consists of the following elements/modules:

•

Heat exchanger is steel plate welded construction. In the upper section of

the boiler is the fuel hopper, which is manually fed with wood logs. This

fuel chamber makes optimal conditions for fuel pyrolisis process and the

volatile gases are directed to the lower section of the boiler, where they

are oxidized in the combustion chamber. In the combustion chamber is

positioned ceramic lining – a nozzle and a flue gas directing element,

which allow efficient combustion process;

•

Combustion nozzle, produced from ceramic material, placed in the lower

section of the fuel hopper, which ensures optimal conditions for efficient

combustion process;

•

Ceramic directing element, which is positioned in the combustion

chamber of the boiler, allowing high temperature levels and ensures

optimal fuel oxidation;

•

Flue gases fan is installed in the back side of the boiler – it transports the

exhausted flue gases out of the boiler and controls the operation of the

boiler;

•

Air distribution box, which has primary air control valve. This box also

serves as heat exchanger and preheats the ambient air before being

consumed in the combustion chamber of the boiler. The inlet of this box

has inflow control flap, which is driven by thermovalve and controls the

total mass flow rate of the air, sucked in the boiler;

•

Inflow orifice has internal thread (for the size see table 2.2) and is

positioned on the back left lower side of the heat exchanger, the outflow

orifice has internal thread as well (for the size see table 2.2) and is

positioned in the back left upper side of the boiler. Use this orifices in

order to connect the boiler to the heating system;

•

Drainage orifice has internal thread (for the size see table 2.2), which

should be connected to a drainage valve;