MAINTENANCE

ZIPPER MASCHINEN GmbH www.Zipper-Maschinen.at

32

ZI-HS10TN / ZI-HS12TN / ZI-HS14TN

17

MAINTENANCE

WARNING

Before carrying out any maintenance work, ensure that moving parts are stationary,

that the machine is disconnected from the mains supply.

17.1

Maintenance Schedule

Activity

Check oil level

After each oil change or every 8 operating hours

Change

hydraulic oil

1 x per year

17.2

Replacing Oil

NOTICE

Check the oil level regularly. Change the hydraulic oil completely at least once a year.

Always dispose of used oil correctly and never throw it into household waste or

sewage!

The hydraulic system of the log splitter is a closed system with oil tank, oil pump and control

valve. The oil should be changed completely once a year.

The following hydraulic oils are recommended for the hydraulic transmission system of the log

splitter:

•

Shell Tellus 22

•

Mobil DTE 11

•

Aral Vitam GF 22 or

•

BP Energol HLP-HM 2

If the oil level is too low, the oil pump can be damaged,

whereas overfilling can lead to overheating of the

hydraulic system. Therefore check the oil level regularly

with the dipstick - see picture on the left!

Waste oils are toxic and must never be

discharged into the environment. If

necessary, contact your local authorities

for information on proper disposal.

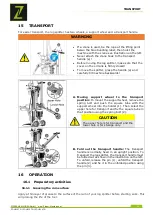

Change the hydraulic oil:

•

Remove the oil drain plug to drain the oil from the hydraulic

system.

•

Use a drip pan to collect waste oil and particles.

•

Inspect the oil for metal chips. (Metal chips in the oil are an

indication of increased wear.)

•

After the oil has been completely drained from the machine,

reinstall the drain plug.

•

Top up the recommended fresh hydraulic oil via the oil filler

plug.

•

Apply a sealant to the oil filler plug and close it again.

•

After changing the oil, actuate the wood splitter several times

without actually splitting any wood.

•

- Use a dipstick to check the oil level.