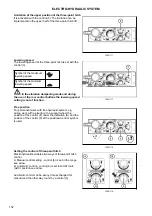

Gauges of the front wheels of the front drive axle of the tractors equipped with screwed footer discs

When using foot discs on a tractor with a power higher exceeding 100 hp, it is necessary to

take extra care and check and tighten the joints more often. It is not recommended to overload the

foot discs.

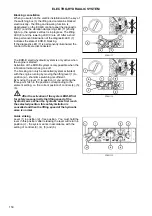

Change of wheel track is done by a change of rim and disc position.

Secure the tractor against movement first, heave the axle with a hoist and support.

Demount front wheels.

Unscrew nuts of screws connecting a disc with rim and protrude the screws.

Change wheel track by setting the rim to a requested position.

Mount the screws back with pads and lock with nuts.

Tighten nuts with a torque of 270 - 300 Nm.

The nut of front wheels to be tightened with a torque of 250 - 290 Nm.

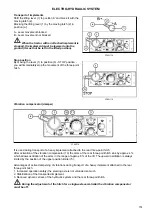

After every release of a foot joint, tighten the screws to a prescribed value.

After travelling a distance of 100 m with an unloaded tractor, retighten the joints to a prescribed

torque.

After tractor run-in tighten the joints after 3 Mh.

After 10 Mh retest the nuts of discs and foots of wheel rim.

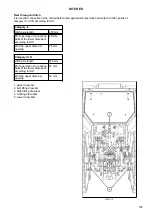

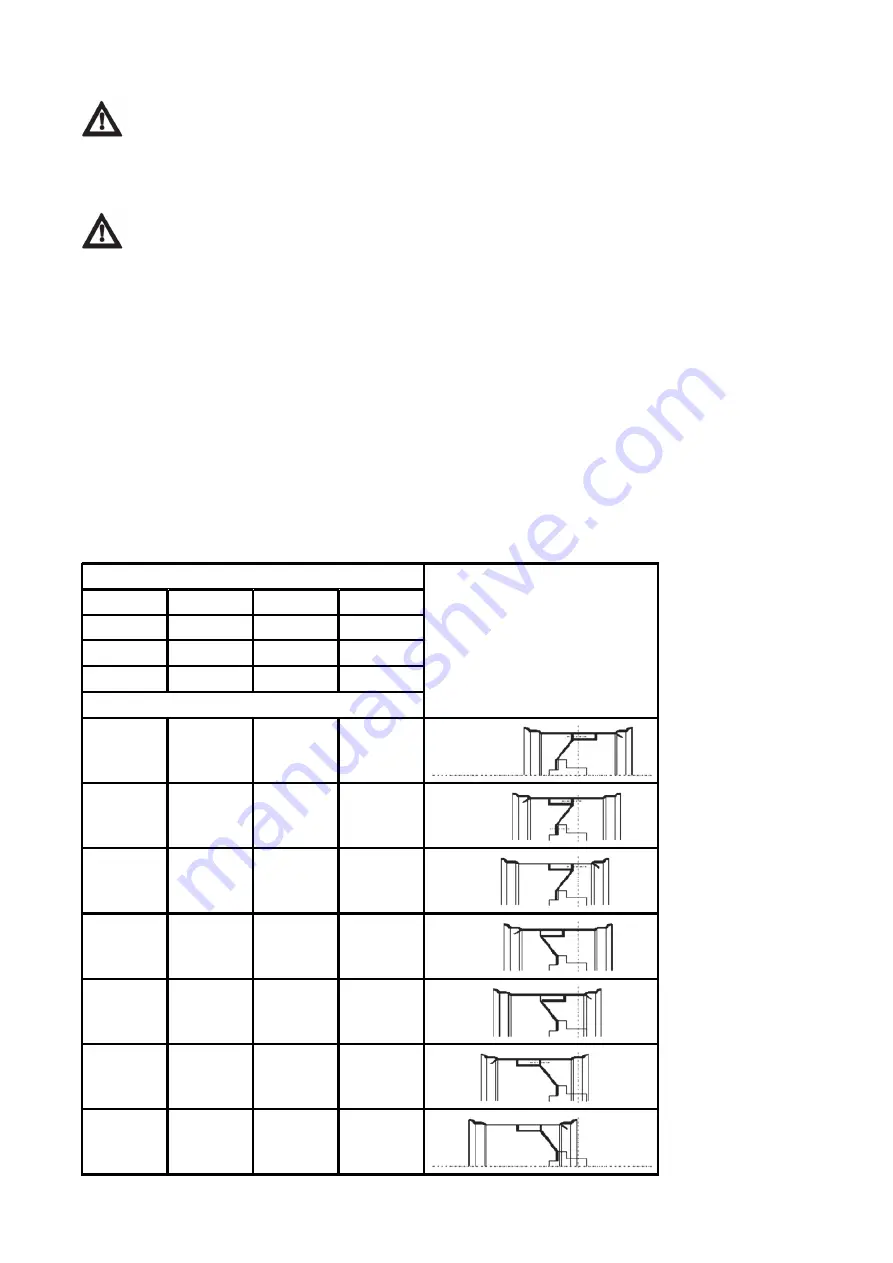

Possible adjustable tracks of the front wheels of the front driving axle of the tractors

Used tyres

Rim position

12,4-24

13,6R24

12,4-28

14,9-24

12,4R24

380/70R24

14,9R24

320/85R24 340/85R24

420/70R24

380/85R24

Front wheel tracks in mm

1630

-

-

-

1685

1770

-

1770

1780

1695

1770

-

1840

1920

1850

1920

1930

1850

1920

1850

1985

2070

1955

2070

2080

1955

2070

1955

WHEEL TRACK CHANG

163

Summary of Contents for FORTERRA HSX 120

Page 1: ...FORTERRA HSX 120 130 Tractor is Zetor Since 1946 140 OPERATOR S MANUAL 04 2020...

Page 3: ...2...

Page 93: ...NOTES 92...

Page 125: ...NOTES 124...

Page 131: ...NOTES 130...

Page 163: ...NOTES 162...

Page 179: ...Fuse panel B Tractors without light controller only FHSXS5N010 ELECTRIC INSTALLATION 178...

Page 181: ...Fuse panel B Tractors with light controller only FHSXS5N008 ELECTRIC INSTALLATION 180...

Page 195: ...NOTES 194...

Page 225: ...NOTES 224...

Page 230: ...229...