Device overview

S7 / OPMI PROergo

Version 11.0

Page 124

G-30-1435-en

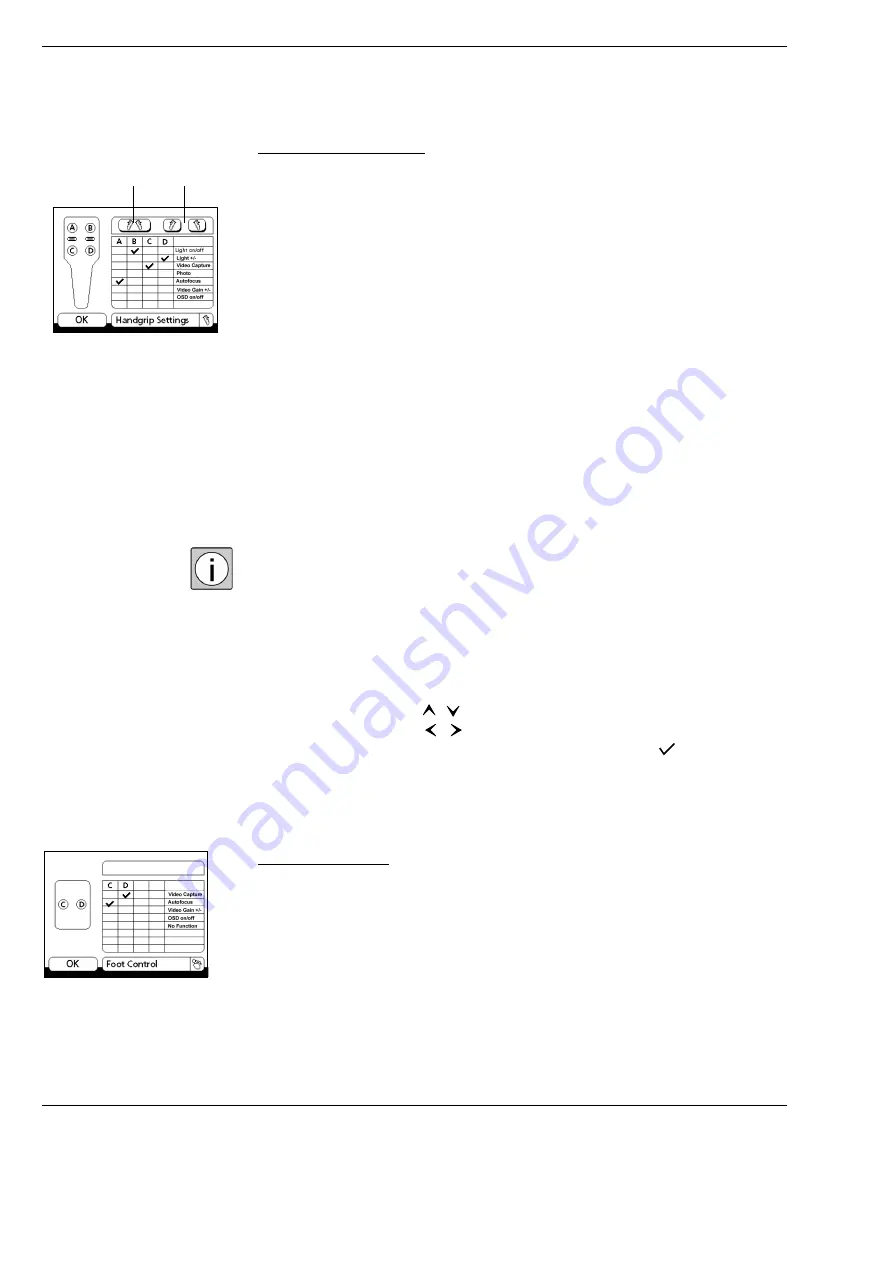

Handgrip Settings menu

This menu allows you to assign one of the listed functions to each of the four

buttons (A, B, C, D) for every user or application:

–

Light on/off: switching the illumination on and off.

–

Light +/-: adjusting the brightness level of the illumination.

–

"Video Capture": triggers the device connected to the "Remote" socket

(on the connector panel of the suspension system).

–

Photo: triggering an electrical contact in the suspension system. Here,

a camera can be connected (option).

–

Autofocus: triggering the SpeedFokus autofocus option.

–

Video Gain +/-: adjusting the brightness level of the integrated video

system (option).

–

OSD on/off: activating/deactivating the on-screen display of the

integrated video system (option).

–

"Freeze/Live": the current live video image is frozen and displayed as a full-

screen freeze frame on the monitor.

The "Video Gain +/-" and the "OSD on/off" functions are offered for selection

only if your system is equipped with an integrated video camera (option).

Without an integrated video camera (option), these fields remain blank.

In addition, you can either assign the same functions to both handgrips by

pressing button (1) or assign different functions to the left and right handgrip

by pressing button (2).

Function assignment:

Use the arrow buttons (

,

) to select the required function from the table.

Use the arrow buttons (

,

) to select the handgrip button required (A-D).

After you have pressed the "Enter" button, a check mark (

) indicates that

the selected function has been assigned to the selected button.

When you press the "Enter" button again, your selection is saved and you

return to the "Surgery" menu.

Foot Control menu

Your suspension system permits the connection of a foot control panel

(option). This menu allows you to assign one of the listed functions to each of

the buttons C and D on the foot control panel for every user:

–

"Video Capture": triggers the device connected to the "Remote" socket

(on the connector panel of the suspension system).

–

Autofocus: triggering the SpeedFokus autofocus option.

1

2

Freeze/Live

Summary of Contents for OPMI PROergo S7

Page 1: ...ZEISS S7 OPMI PROergo Instructions for Use G 30 1435 en Version 11 0 2018 11 30...

Page 3: ...Version 11 0 G 30 1435 en Page 3 S7 OPMI PROergo be prevented...

Page 4: ...S7 OPMI PROergo Version 11 0 Page 4 G 30 1435 en...

Page 6: ...S7 OPMI PROergo Version 11 0 Page 6 G 30 1435 en...

Page 25: ...Version 11 0 G 30 1435 en Page 25 S7 OPMI PROergo Safety measures 3 1 2 2...

Page 27: ...Version 11 0 G 30 1435 en Page 27 S7 OPMI PROergo Safety measures...

Page 29: ...Version 11 0 G 30 1435 en Page 29 S7 OPMI PROergo Safety measures 1 2 6 3 4 1 7 8 2 5...

Page 33: ...Version 11 0 G 30 1435 en Page 33 S7 OPMI PROergo Safety measures 5 3 1 1 1 1 2 6 4...

Page 35: ...Version 11 0 G 30 1435 en Page 35 S7 OPMI PROergo Safety measures 8 10 7 9...

Page 37: ...Version 11 0 G 30 1435 en Page 37 S7 OPMI PROergo Safety measures 11 13 12...

Page 39: ...Version 11 0 G 30 1435 en Page 39 S7 OPMI PROergo Safety measures 1...

Page 41: ...Version 11 0 G 30 1435 en Page 41 S7 OPMI PROergo Safety measures 1 1 5 2 1 3 4 7 9 8 5 6...

Page 45: ...Version 11 0 G 30 1435 en Page 45 S7 OPMI PROergo Safety measures 1 2...

Page 47: ...Version 11 0 G 30 1435 en Page 47 S7 OPMI PROergo Safety measures 1 1 5 2 1 3 4 7 9 8 5 6...

Page 53: ...Version 11 0 G 30 1435 en Page 53 S7 OPMI PROergo Safety measures 1 2 3 4 5 6...

Page 56: ...Safety measures S7 OPMI PROergo Version 11 0 Page 56 G 30 1435 en...

Page 59: ...Version 11 0 G 30 1435 en Page 59 S7 OPMI PROergo Device overview...

Page 63: ...Version 11 0 G 30 1435 en Page 63 S7 OPMI PROergo Device overview 2 6 4 1 5 6 3 6 6 6...

Page 65: ...Version 11 0 G 30 1435 en Page 65 S7 OPMI PROergo Device overview 4 5 6 2 1 2 3...

Page 67: ...Version 11 0 G 30 1435 en Page 67 S7 OPMI PROergo Device overview 1 3 4 2 5 6 1 2 2 1 7...

Page 69: ...Version 11 0 G 30 1435 en Page 69 S7 OPMI PROergo Device overview 10 13 11 12 9 8...

Page 75: ...Version 11 0 G 30 1435 en Page 75 S7 OPMI PROergo Device overview 1 2 3...

Page 77: ...Version 11 0 G 30 1435 en Page 77 S7 OPMI PROergo Device overview 1 2 3 4 5 6 7 8 9...

Page 79: ...Version 11 0 G 30 1435 en Page 79 S7 OPMI PROergo Device overview 1 2 3 4...

Page 81: ...Version 11 0 G 30 1435 en Page 81 S7 OPMI PROergo Device overview 1 2 3 4 5 6 7 8 9...

Page 85: ...Version 11 0 G 30 1435 en Page 85 S7 OPMI PROergo Device overview 1 3 4 2 1...

Page 87: ...Version 11 0 G 30 1435 en Page 87 S7 OPMI PROergo Device overview 1 2 3 4 5 7 6...

Page 89: ...Version 11 0 G 30 1435 en Page 89 S7 OPMI PROergo Device overview 1 2 3 4 5 6 7 8...

Page 91: ...Version 11 0 G 30 1435 en Page 91 S7 OPMI PROergo Device overview 1 4 2 3 6 5 7 8 9...

Page 93: ...Version 11 0 G 30 1435 en Page 93 S7 OPMI PROergo Device overview 1 2 3 4 5 7 6...

Page 95: ...Version 11 0 G 30 1435 en Page 95 S7 OPMI PROergo Device overview 1 2...

Page 97: ...Version 11 0 G 30 1435 en Page 97 S7 OPMI PROergo Device overview 1 2 3 4 5 6 7 8...

Page 101: ...Version 11 0 G 30 1435 en Page 101 S7 OPMI PROergo Device overview 1 2 3 4 5 6...

Page 103: ...Version 11 0 G 30 1435 en Page 103 S7 OPMI PROergo Device overview 1 2 3 4 5 6 7 8...

Page 105: ...Version 11 0 G 30 1435 en Page 105 S7 OPMI PROergo Device overview 1 4 2 3 6 5 7 8 9...

Page 107: ...Version 11 0 G 30 1435 en Page 107 S7 OPMI PROergo Device overview 1 2...

Page 109: ...Version 11 0 G 30 1435 en Page 109 S7 OPMI PROergo Device overview 2 1...

Page 111: ...Version 11 0 G 30 1435 en Page 111 S7 OPMI PROergo Device overview 1 2 3 4 5 6...

Page 113: ...Version 11 0 G 30 1435 en Page 113 S7 OPMI PROergo Device overview 2 1 6 7 5...

Page 115: ...Version 11 0 G 30 1435 en Page 115 S7 OPMI PROergo Device overview 2 4 3 6 3 7 5...

Page 133: ...Version 11 0 G 30 1435 en Page 133 S7 OPMI PROergo Device overview...

Page 137: ...Version 11 0 G 30 1435 en Page 137 S7 OPMI PROergo Device overview 1 3 2...

Page 143: ...Version 11 0 G 30 1435 en Page 143 S7 OPMI PROergo Preparations for use 1 3 4 5 6 7 2...

Page 147: ...Version 11 0 G 30 1435 en Page 147 S7 OPMI PROergo Preparations for use 3 1 2 4 5...

Page 149: ...Version 11 0 G 30 1435 en Page 149 S7 OPMI PROergo Preparations for use 1 2...

Page 151: ...Version 11 0 G 30 1435 en Page 151 S7 OPMI PROergo Preparations for use 1 2...

Page 153: ...Version 11 0 G 30 1435 en Page 153 S7 OPMI PROergo Preparations for use 1 2...

Page 159: ...Version 11 0 G 30 1435 en Page 159 S7 OPMI PROergo Preparations for use...

Page 165: ...Version 11 0 G 30 1435 en Page 165 S7 OPMI PROergo Preparations for use 1 2...

Page 171: ...Version 11 0 G 30 1435 en Page 171 S7 OPMI PROergo Preparations for use 4 1 2 1 2 2 1 3 5...

Page 178: ...Preparations for use S7 OPMI PROergo Version 11 0 Page 178 G 30 1435 en...

Page 198: ...What to do in the event of malfunctions S7 OPMI PROergo Version 11 0 Page 198 G 30 1435 en...

Page 219: ...Version 11 0 G 30 1435 en Page 219 S7 OPMI PROergo Care and maintenance...

Page 221: ...Version 11 0 G 30 1435 en Page 221 S7 OPMI PROergo Care and maintenance 1 2 5 6 4 7 3...

Page 226: ...Care and maintenance S7 OPMI PROergo Version 11 0 Page 226 G 30 1435 en...

Page 258: ...Device data S7 OPMI PROergo Version 11 0 Page 258 G 30 1435 en...

Page 266: ...Keyword index S7 OPMI PROergo Version 11 0 Page 266 G 30 1435 en...

Page 267: ...Version 11 0 G 30 1435 en Page 267 S7 OPMI PROergo Blank page for your notes...