Y Z S y s t e m s M i l t o n R o y • 2 0 1 I v y l a n d R o a d • I v y l a n d , PA • U S A • 1 8 9 7 4 • P : 2 8 1 . 3 6 2 . 6 5 0 0 • w w w. y z s y s t e m s . c o m

Page 37

NJEX 610G / 610F ver.11-2023

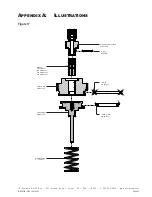

Appendix A: Illustrations

Figure 20

Z-100 CONTROLLER

FLOW SWITCH (OPTIONAL)

SOLENOID

LVO SYSTEM

xxxx

YYYY

DYNAPAK SYSTEM

Z-100 CONTROLLER

SOLENOID

CYCLONE SYSTEM

Z-100 CONTROLLER

SOLENOID

SYSTEM LEVEL CONNECTIONS

MADE AT Z-100 CONTROLLER:

RELAY +

1.

RELAY -

2.

ANALOG IN

3.

COMMON

4.

FLOW SWITCH

5.

EXT. POWER

6.

COMMON

7.

NBS IN

8.

COUNT IN

9.

SOLENOID -

10.

S

11.

THIS WIRING CONTROL DOCUMENT COVERS THE FOLLOWING YZ SYSTEMS PR

ODUCT LINES USING THE Z-100 CONTROLLER:

LVO LOW VOLUME ODORIZER 610G OR 610F DYNAPAK 20X0, 30X0 CYCLONE MLS-4400

THE SYSTEMS LISTED ABOVE HOLD THE FOLLOWING APPROVALS:

CLASS I, DIVISION 1, GROUPS C-D, T4 PROVIDES INTRINSICALLY SAFE OUTPUTS FOR CLASS I, DIVISION 1, GR

OUPS C-D AND CLASS I, ZONE 0, GROUP IIB

CLASS I, ZONE 0, AEx ia [ia] IIB T4 Ga Ex ia [ia] IIB T4 Ga II 1(1)G Ex ia [ia] IIB T4 Ga -20

C ≤ Ta ≤ +60

C

IP54

ETL23CA104230006X IECEx ETL 23.0013X ETL23ATEX0290X ITS23UKEX0707X

Conforms to UL STD 60079-0, 60079-11, 61010-1 Certified to CSA STD C22.2 NO. 60079-0, 60079-11, 61010-1-12

INTRINSICALLY SAFE INTRINSEQUEMENT SUR

SPECIAL CONDITIONS OF USE

ALL SYSTEMS ARE INTENDED FOR FIXED INSTALLATION

1.

POTENTIAL ELECTROSTATIC CHARGING HAZARD. EQUIPMENT SHALL BE CL

EANED WITH A DAMP CLOTH.

2.

YZ SYSTEMS - SYSTEM LEVEL WIRING CONTROL DOCUMENT

SYSTEMS USING Z-100 CONTROLLER

NOTES:

EX

SCHEDULE DRAWING - DO NOT MODIFY WITHOUT AGENCY APPROVAL.

1.

ASSEMBLIES SHOWN DO NOT COVER ALL CONFIGURATIONS FOR EACH PRO

DUCT LINE.

2.

REFER TO THE MODEL CODE ABOVE FOR ALL MODELS COVERED UNDER THIS

DOCUMENT.

SEE WIRING CONTROL DOCUMENT 2E-0042 FOR ALL WIRING AND APPROVAL

S

3.

INFORMATION ON THE Z-100 CONTROLLER.

3193094

Z-100 CONTROLLER

External I.S. Supply Ui: 28VDC Ii: 178mA Pi: 1.245W

Internal Battery Pack Ui: 15.6VDC Ii: 299.18mA Pi: 1.054W

SOLENOID

50mA @ 12VDC

NOMINAL

FLOW SWITCH

(LVO 610F

MODELS ONLY)

SEE WIRING CONTROL DOCUMENT 2E-0042 FOR ALL WIRING DETAILS

FOR CONTROLLER

DATE

ECN

DESCRIPTION

Drawn -

Dessiné / Visa

Checked - Vérifié / Visa

REV

REVISION HISTORY

7/6/2023

29593

DRAFT RELEASE

TRA

SS

00

12

H

G

F

E

D

C

B

A

J

K

L

M

N

P

Q

R

A

B

C

D

E

F

G

H

J

K

L

M

N

P

11

10

9

8

7

6

5

4

3

2

1

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

23

21

24

22

T

R

REV

2000 - 4000

2[.079]

1000 - 2000

1.2[.047]

400 - 1000

0.8[.031]

120 - 400

0.5[.020]

30 - 120

0.3[.012]

6 - 30

0.2[.008]

GENERAL TOLERANCE

ISO 2768

FIRST ANGLE PROJECTION

DO NOT SCALE DRAWING

DESSIN SANS ECHELLE

0.2

[0.079]

0.6

[0.024]

0.4

[0.016]

TOLERANCES mm[ INCHES]

125

RMS

Ra

FINISH

SHEET - FEUILLE

GEOMETRIC TOLERANCES

TOLÉRANCES GÉOMÉTRIQUES

LINEAR DIMENSIONS - DIMENSIONS LINÉAIRES mm[INCHES]

DESCRIPTION

A0

1

/

1

<3.2

DRAWING NUMBER - PLAN N°

.5 - 6

FORMAT TAILLE

0.1[.004]

2E-0054

WIRING CONTROL DOCUMENT

00

LVO, DP, CYCLONE SYSTEMS

PROPRIETARY NOTICE

THIS DRAWING CONTAINS CONFIDENTIAL AND TRADE SECRET INFORMATION. IS THE PROPERTY OF INGERSOLL-RAND CO., AND IS GIVEN TO THE RECEIVER IN CONFIDENCE. THE RECEIVER BY RECEPTION AND RETENTION OF THE DRAWING ACCEPTS THE DRAWING IN CONFIDENCE AND AGREES THAT, EXCEPT AS AUTHORIZED IN WRITING BY INGERSOLL-RAND CO., IT WILL (1) NOT USE THE DRAWING OR ANY COPY THEREOF OR THE CONFIDENTIAL OR TRADE SECRET INFORMATION THEREIN; (2) NOT COPY THE DRAWING; (3) NOT DISCLOSE TO OTHERS EITHER THE DRAWING OR THE CONFIDENTIAL OR TRADE SECRET INFORMATION THEREIN; AND (4) UPON COMPLETION OF THE NEED TO RETAIN THE DRAWING, OR UPON DEMAND, RETURN THE DRAWING, ALL COPIES THEREOF, AND ALL MATERIAL COPIED THEREFROM.

WARNING: THE EXPORT OR REEXPORT OF THIS DRAWING OR A PRODUCT PR

ODUCED BY THIS DRAWING IS SUBJECT TO U.S. EXPORT

ADMINISTRATION REGULATIONS AND OTHER APPLICABLE GOVERNMENT REST

RICTIONS OR REGULATIONS