JOHNSON CONTROLS

65

SECTION 4 - OPERATIONAL MAINTENANCE

FORM 160.67-O2

ISSUE DATE: 10/9/2020

4

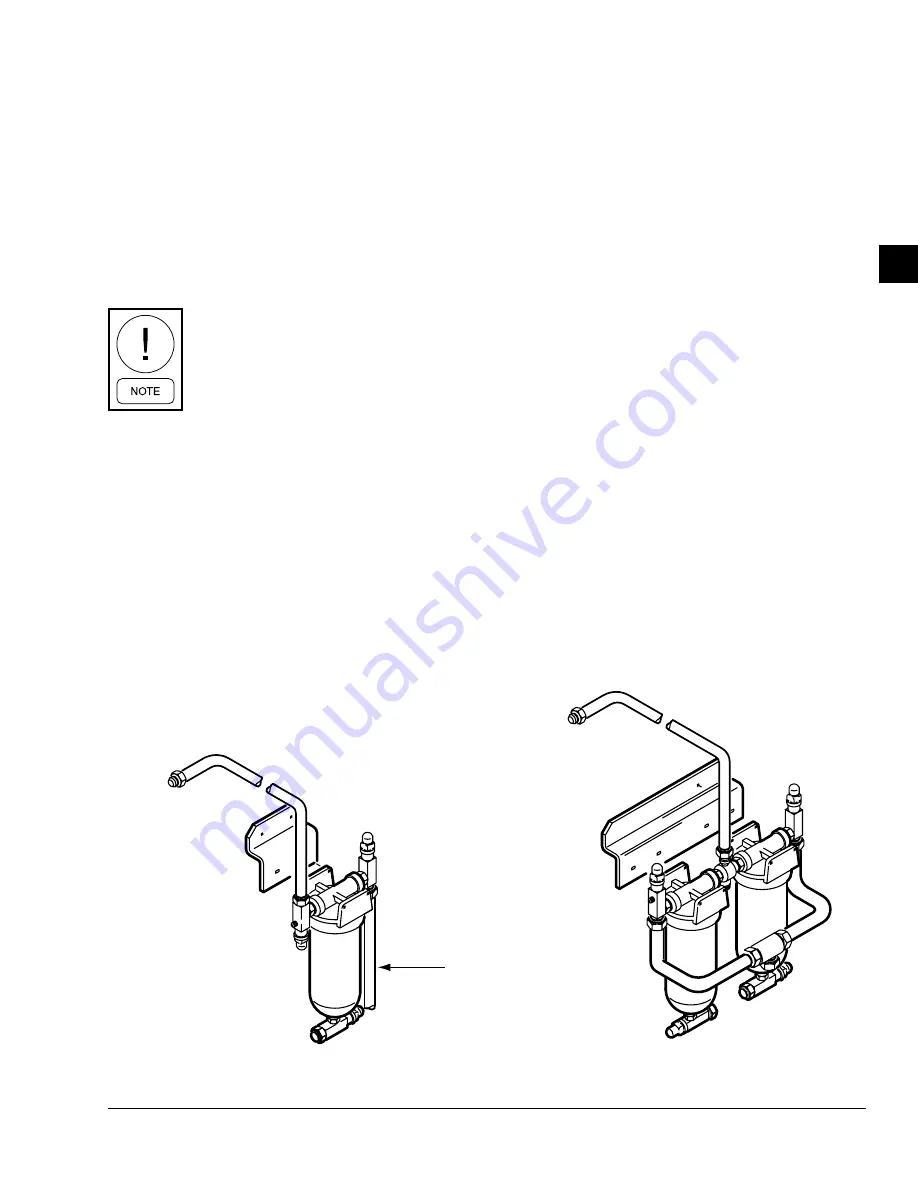

COMPRESSOR OIL FILTER

A single oil filter is provided as standard equipment

and dual oil filter arrangements are available as option-

al equipment. The oil filter(s) are a replaceable 3 mi-

cron cartridge type oil filter. Use only YORK approved

oil filter elements.

The oil filter element should be changed after the first

200 hours of operation and then as necessary thereaf

-

ter. Always replace the oil filter element and O-ring on

a yearly maintenance schedule.

When the Compressor Oil Pump VSD

frequency increases to 55 Hz to maintain

the target oil pressure, the Compressor Oil

Filter is dirty and needs to be replaced.

Single Oil Filter Replacement

The chiller must be OFF. Place the Keypad control

switch to the OFF position; turn the main disconnect

switch on the power panel to the OFF position to pre-

vent the chiller from being accidentally started.

1. Close the hand isolation valves on the inlet and

outlet oil lines going to and from the oil filter.

2.

Relieve the refrigerant pressure and oil in the oil

filter and the oil lines through the pressure access

port fitting, located on the top of the filter housing.

Connect a refrigeration pressure hose to the pres-

sure access port and drain the oil and refrigerant

into a suitable refrigerant recovery container.

3.

Position a container to collect the oil (less than 2

quarts, 1.9 liters). Loosen and remove the drain

nut at the bottom of the oil filter housing; drain the

oil into the container.

4.

Unscrew the oil filter bowl locking nut.

5. Remove the oil filter element.

6.

Install a new element.

7.

Install a new O-ring on the top of the oil filter

bowl.

8. Tighten the oil filter bowl locking nut.

9.

Open the hand isolation valves.

10. The chiller is ready to be restarted.

FIGURE 16 -

STANDARD SINGLE OIL FILTER AND OPTIONAL DUAL OIL FILTER

LD010025

To Thermostatic

Control Valve

To Compressor

To Compressor