5169034-UIM-B-0216

14

Johnson Controls Unitary Products

SECTION X: MAINTENANCE

Filters must be cleaned or replaced when they become dirty. Inspect at

least once per month. The frequency of cleaning depends upon the

hours of operation and the local atmospheric conditions. Clean filters

keep unit efficiency high.

COIL CLEANING

If the coil needs to be cleaned, it should be cleaned with water.

LUBRICATION

The bearings of the blower motor are permanently lubricated.

CONDENSATE DRAINS

During the cooling season check the condensate drain lines to be sure

that condensate is flowing from the primary drain but not from the

secondary drain. If condensate ever flows from the secondary drain the

unit should be promptly shut off and the condensate pan and drains

cleaned to insure a free flowing primary drain.

SECTION XI: AIR SYSTEM ADJUSTMENT

To check the Cubic Feet per Minute (CFM), measure the static

pressure drop across the air handler using a manometer and static

pressure tips. To prepare coil for static pressure drop measurements

run the fan only to assure a dry coil.

Drill 2 holes, one 12” away from the air handler in the supply air duct

and on 12” away from the air handler in the return air duct (before any

elbows in the duct work). Insert the pressure tips and read the pressure

drop from the manometer. See Table 9 to determine the air flow, and

make the necessary adjustments to keep the CFM within the airflow

limitations of the coil.

EXTERNAL DUCT STATIC

Measure the supply air static pressure. Record this positive number.

Measure the return air static pressure. Record this negative number.

Treat the negative number as a positive, and add the two numbers to-

gether. This is total system static. If a filter rack is installed on the return

air end of the air handler or indoor coil section, the return air duct static

must be measured between the filter and the indoor coil.

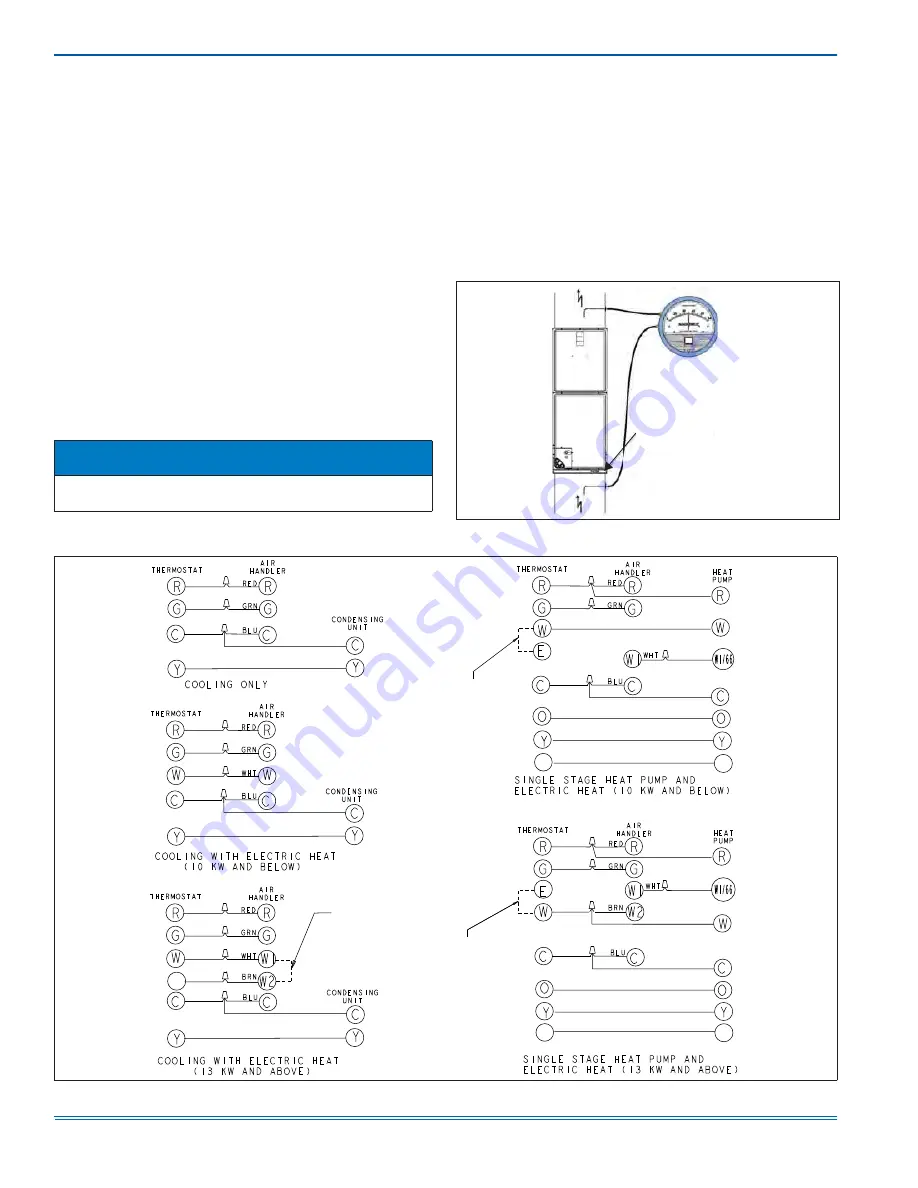

SECTION XII: TYPICAL THERMOSTAT CONNECTIONS

NOTICE

Refer to Table 9 for coil Air Flow Data of Cubic Feet Per Minute

(CFM). Run the fan on the highest speed to be used.

T

a

k

e

measurements

h

ere

if

using

a

fil

ter

ra

ck.

R

eturn

air

stati

c

must

b

e

ta

k

en

b

et

w

een

t

h

e

fil

ter

and

ind

oo

r

co

i

l.

A

0

3

9

5-

001

FIGURE 11:

Typical Thermostat Wiring Diagram - ECM

$

:.

:.

:.

:.

:

),(/',167$//('

-803(5,)6,1*/(

67$*(7+(50267$7

,686('

),(/'

,167$//('

-803(5,)

5(48,5('

),(/'

,167$//('

-803(5,)

5(48,5('