<2. Handling Cautions>

12

IM 01C25A01-01E

Model: EJX910A-F Series

Date: September 9, 2005

Rev.2: July 16, 2019

Doc. No.:

IFM026-A12 P.2

Yokogawa Electric Corporation

IFM026

Specific conditions of use:

-

Precautions shall be taken to minimize the risk from electrostatic discharge of

painted parts.

-

When the enclosure of the Pressure Transmitters is made of aluminum alloy, if it is

mounted in Zone 0, it shall be installed such that, even in the event of rare incidents,

an ignition source due to impact and/or friction sparks is excluded.

Supply circuit:

Entity parameters [Groups: A, B, C, D, E, F, G, and IIC]

Ui: 24 V

Ii: 250 mA

Pi: 1.2 W

Ci: 3.52 nF

Li: 0 µH

FISCO parameters (1) [Groups: A, B, C, D, E, F, G, and IIC]

Ui: 17.5 V

Ii: 380 mA

Pi: 5.32 W

Ci: 3.52 nF

Li: 0 µH

FISCO parameters (2) [Groups: C, D, E, F, G, and IIB]

Ui: 17.5 V

Ii: 460 mA

Pi: 5.32 W

Ci: 3.52 nF

Li: 0 µH

Sensor circuit:

Entity parameters [Groups: A, B, C, D, E, F, G, and IIC]

Uo: 6.51 V

Io: 4 mA

Po: 6 mW

Co: 34 µF

Lo: 500 mH

Model: EJX910A-F Series

Date: September 9, 2005

Rev.2: July 16, 2019

Doc. No.:

IFM026-A12 P.3

Yokogawa Electric Corporation

IFM026

Notes:

1.

Installation must be in accordance with the National Electric Code (NFPA70),

ANSI/ISA-RP12.06.01, and relevant loc al codes.

2.

The Associated Apparatus and the Terminators must be FM -approved.

3.

The following conditions must be satisfied.

4.

General Purpose Equipment connected to the Associated Apparatus must not use or

generate a voltage more than Um of the Associated Apparatus.

5.

The control drawing of the Associated Apparatus must be followed when installing the

equipment.

6.

Dust-tight conduit seals must be used when installed in Class II or Class III

environments.

7.

WARNING –ELECTROSTATIC CHARGE MAY CAUSE AN EXPLOSION HAZARD.

AVOID ANY ACTIONS THAT CAUSE THE GENERATION OF ELECTROSTATIC

CHARGE, SUCH AS RUBBING WITH A DRY CLOTH ON COATING FACE OF THE

PRODUCT.

8.

WARNING – SUBSTITUTION OF COMPONENTS MAY IMPAIR INTRINSIC SAFETY

AND SUITABILITY FOR HAZARDOUS LOCATION

FISCO Rules

The FISCO Concept allows the interconnection of intrinsically safe apparatus to associated apparatus

not specifically examined in such combination. The criterion for such interconnection is that the

voltage (Ui), the current (Ii) and the power (Pi) which intrinsically safe apparatus can receive and

remain intrinsically safe, considering faults, must be equal or greater than the voltage (Uo, Voc or Vt),

the current (Io, Isc or It) and the power (Po) which can be provided by the associated apparatus

(supply unit). In addition, the maximum unprotected residual capacitance (Ci) and inductance (Li) of

each apparatus (other than terminators) connected to the Fieldbus must be less than or equal to 5 nF

In each I.S. Fieldbus segment only one active source, normally the associated apparatus, is allowed to

provide the necessary power for the Fieldbus system. The allowed voltage (Uo, Voc or Vt) of the

associated apparatus used to supply the bus cable must be limited to the range of 14 V d.c. to 17.5 V d.c.

All other equipment connected to the bus cable has to be passive, meaning that the apparatus is not

allowed to provide energy to

Separately powered equipment needs galvanic isolation to ensure the intrinsically safe Fieldbus

circuit remains passive.

The cable used to interconnect the devices needs to comply with the following parameters:

Inductance per unit length L': 0.4....1 mH/km

Capacitance per unit length C': 45....200 nF/km C' = C' line/line + 0.5 C' line/screen, if both lines are

floating or C' = C' line/line + C'line/screen, if the screen is connected to one line.

Length of spur cable: max. 60 m

Length of trunk cable: max. 1 km in IIC and 5 km in IIB

Length of splice: max = 1 m

Terminators

At the end of each trunk cable an FM Approved line terminator with the following parameters is

suitable:

Model: EJX910A-F Series

Date: May 22, 2006

Rev.1: July 16, 2019

Doc. No.:

IFM026-A12 P.3-1

Yokogawa Electric Corporation

IFM026

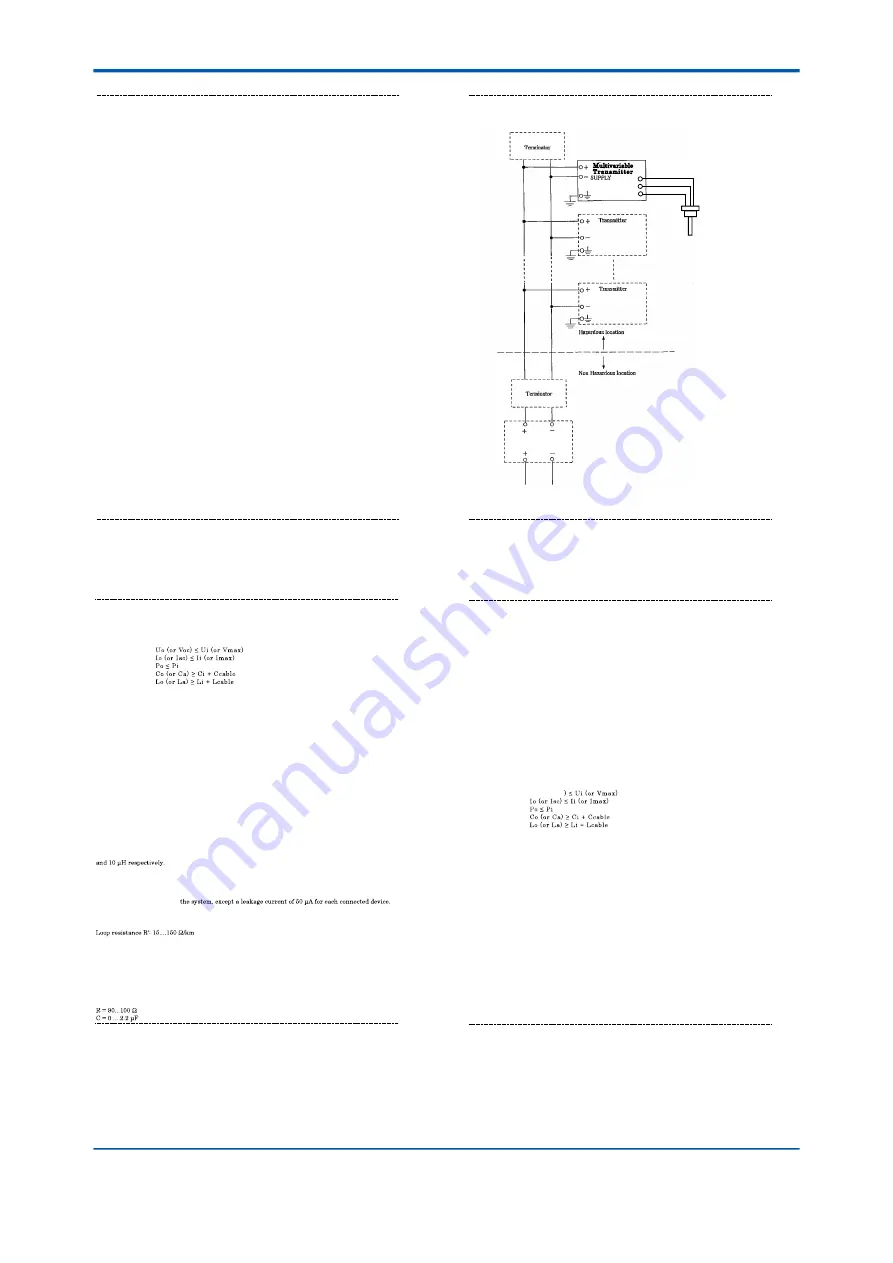

Control drawing (nonincendive)

(Refer to Note 3)

General Purpose

Equipment

Multivariable

Transmitter

Sensor circuit

Class I, II, Division 2

Groups A, B, C, D , F, G

Class III, D ivision 1

Class I, Zone 2, Group IIC

Certified Equipment

or

Simple Apparatus

Model: EJX910A-F Series

Date: May 22, 2006

Rev.3: July 16, 2019

Doc. No.:

IFM026-A12 P.3-2

Yokogawa Electric Corporation

IFM026

Nonincendive field wiring parameters

Supply circuit:

Vmax: 32 V

Ci: 3.52 nF

Li: 0 µH

Sensor circuit:

Vt: 6 V

It: 25 mA

Po: 0.15 W

Ca: 40 µF

La: 40 mH

Notes:

1.

Installation must be in accordance with the National Electric Code (NFPA70),

ANSI/ISA-RP12.06.01, and relevant local codes.

2.

The following conditions must be satisfied.

3.

In case Nonincendive Field Wiring Concept is used for the interconnection,

FM-approved Associated Nonincendive Field Wiring Apparatus, which meets the

following conditions, must be used as the General Purpose Equipment. The

Terminators also must be FM approved.

Uo (or Voc

Dust-tight conduit seals must be used when installed in Class II or Class III

environments.

4.

WARNING – SUBSTITUTION OF COMPONENTS MAY IMPAIR INTRIN SIC SAFETY

AND SUITABILITY FOR HAZARDOUS LOCATION