YMGI

•

Your Modern Green Idea

36

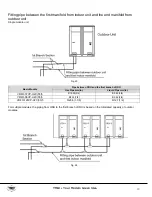

Fixing point 3: 250 mm on the branched pipe from the welding point

Fig. 34

4. Thermal insulation for pipeline

1) To avoid condensate or water leakage on connecting pipe, the gas pipe and liquid pipe must be

wrapped with thermal insulating material and adhesive pipe for insulation from

2) For heat pump unit, liquid pipe should bear 70ºC (158ºF) or above, and gas pipe should bear 120ºC

(248ºF) or above. For cooling only unit, both liquid pipe and gas pipe should bear 70ºC (158ºF) or

above. Example: Polyethylene foam can bear 120ºC (248ºF) above and foaming polyethylene can bear

100ºC (212

℉

) above.

3) Joints at indoor and outdoor units should be wrapped with insulating material and leave no clearance

between pipe and wall. See Fig.35.

Fig. 35

4) Manifold attached foam cannot be taken as insulating material.

5)

When wrapping the tape, the later circle should cover half of the former one. Don’t wrap the tape so

tightly, otherwise the insulation effect will be weakened.

6) After wrapping the pipe, adopt sealing material to completely fill the hole so as to prevent wind and rain

from entering the room.

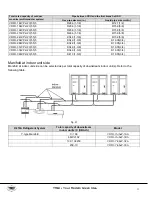

Support and protection for pipeline

1.

Support should be made for hanging connection pipe. Distance between each support cannot be over 1m (39-

3/8in.).

2.

Protection against accidental damage should be made for outdoor pipeline. When the pipeline exceeds 1m (39-

3/8in.), a pin. board should be added for protection.