Changing the Optical Output Power and Diode Current

34

TUNICS T100S-HP User Manual

The active mode is

constant-power

: the laser-diode current is controlled to ensure

an optical power output equal to the

P

parameter.

By pressing the

P

function key, the system switches automatically to the constant-

power mode.

In this mode, the required power cannot be obtained, even with the maximum

allowable current. In this case:

•

The current is limited to its maximum value.

•

The optical power is lower than the user-set power value.

•

The

Lim

message is displayed to the right of the current and power values.

•

To activate the constant-current mode, press the APC function key to turn

off

the APC

key LED:

The active mode is

constant-current

: the diode current level is determined by the

I

parameter.

By pressing the

I

function key, the system switches automatically to the constant-

current mode.

5.3

Disabling/Enabling Active Cavity Control

Subject

The TUNICS T100S-HP is equipped with on-board active cavity control.

When you turn on the TUNICS T100S-HP after the initialization routine is complete, the

system switches automatically to APC (constant power) mode with active cavity control

(the APC LED is on).

Active Cavity Control Requirements

Active cavity control is enabled if the following requirements are both met:

•

APC (constant power) mode (APC LED on)

•

Power > 0.8 mW

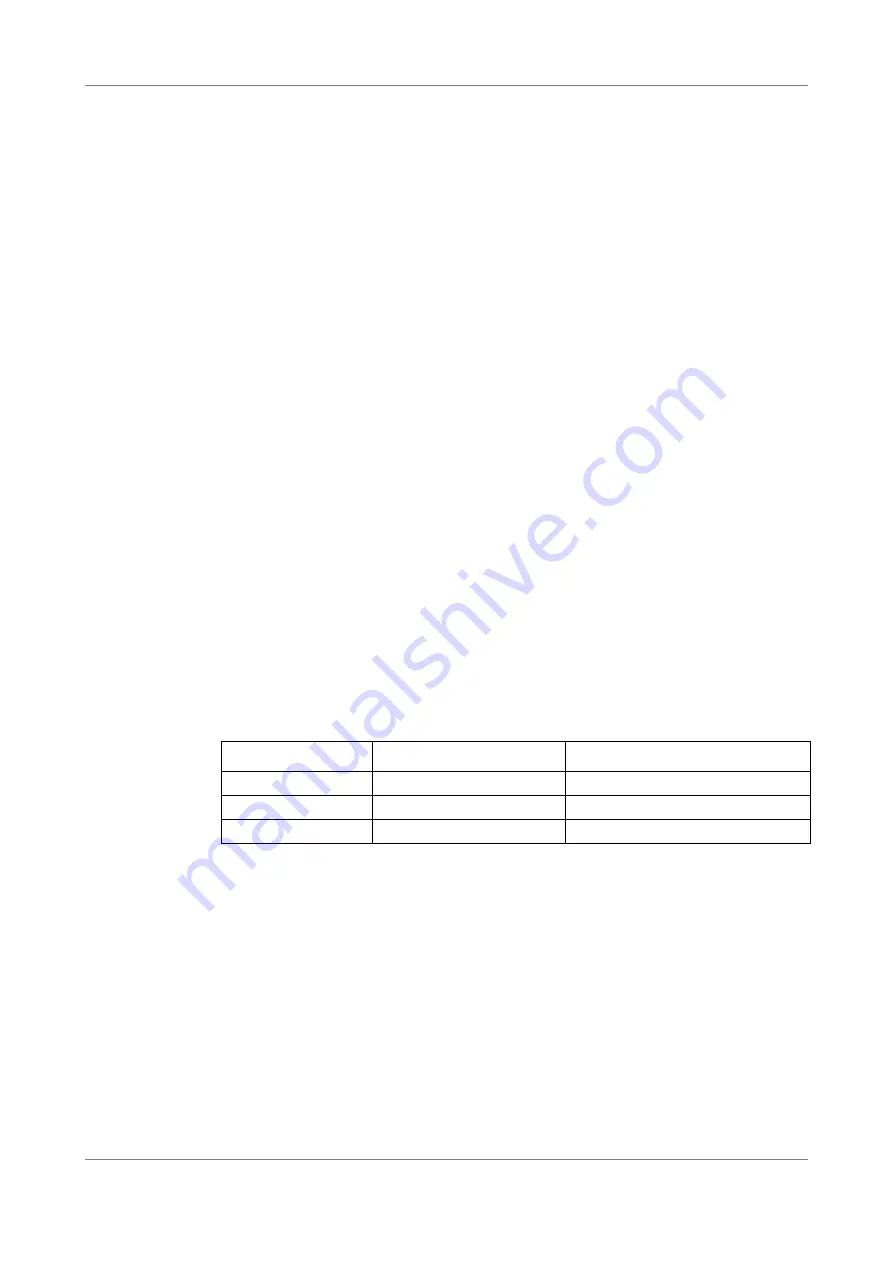

System Status

System status is summarized in the following table:

Table 11: Active Cavity Control - System Status

Procedure

•

To disable active cavity control, press the

2nd

+

APC

key combination.

The

APC

LED blinks.

If you press the

APC

key and the APC LED goes off, this indicates that the system has

switched in constant current mode. When entering constant current mode, the active

cavity control becomes disabled, and the system restores the operating parameters

that were in effect at the time the TUNICS T100S-HP last left the constant current

mode.

•

To enable active cavity control, press the

2nd

+

APC

command keys again.

If the APC LED starts blinking while the TUNICS T100S-HP is in APC mode with active

cavity control on, this may indicate that the laser power output (P) is set to a value

lower than the 0.8 mW threshold.

APC LED

Constant Power Mode

Active Cavity Control

On

Yes

Yes

Blinking

Yes

No

Off

No

No

Summary of Contents for TUNICS T100S-HP

Page 2: ......

Page 6: ...About This Manual 6 TUNICS T100S HP User Manual...

Page 24: ...Installing and Connecting the Product 24 TUNICS T100S HP User Manual...

Page 36: ...Changing the Optical Output Power and Diode Current 36 TUNICS T100S HP User Manual...

Page 50: ...Using the Auxiliary Inputs and Outputs 50 TUNICS T100S HP User Manual...

Page 54: ...Verifying Performances 54 TUNICS T100S HP User Manual...

Page 60: ...Certification and Compliance 60 TUNICS T100S HP User Manual...