8.12 Manual Tuning

8.12.2 Compatible Adjustment Functions

8-79

8

T

uning

Note: 1. Overshooting will occur if you set the torque feedforward too high. Set the optimum value while monitoring

the response.

2. You cannot use the torque feedforward function together with torque limiting with an analog voltage refer-

ence.

Speed Feedforward

You set the speed feedforward function with the position control option (Pn207 = n.

X

)

and the speed reference input gain (Pn300).

The default setting of Pn300 is 600. Therefore, if the speed feedforward value is

±

6 V, then it

will indicate the rated speed.

Note: Overshooting will occur if you set the feedforward too high. Set the optimum value while monitoring the

response.

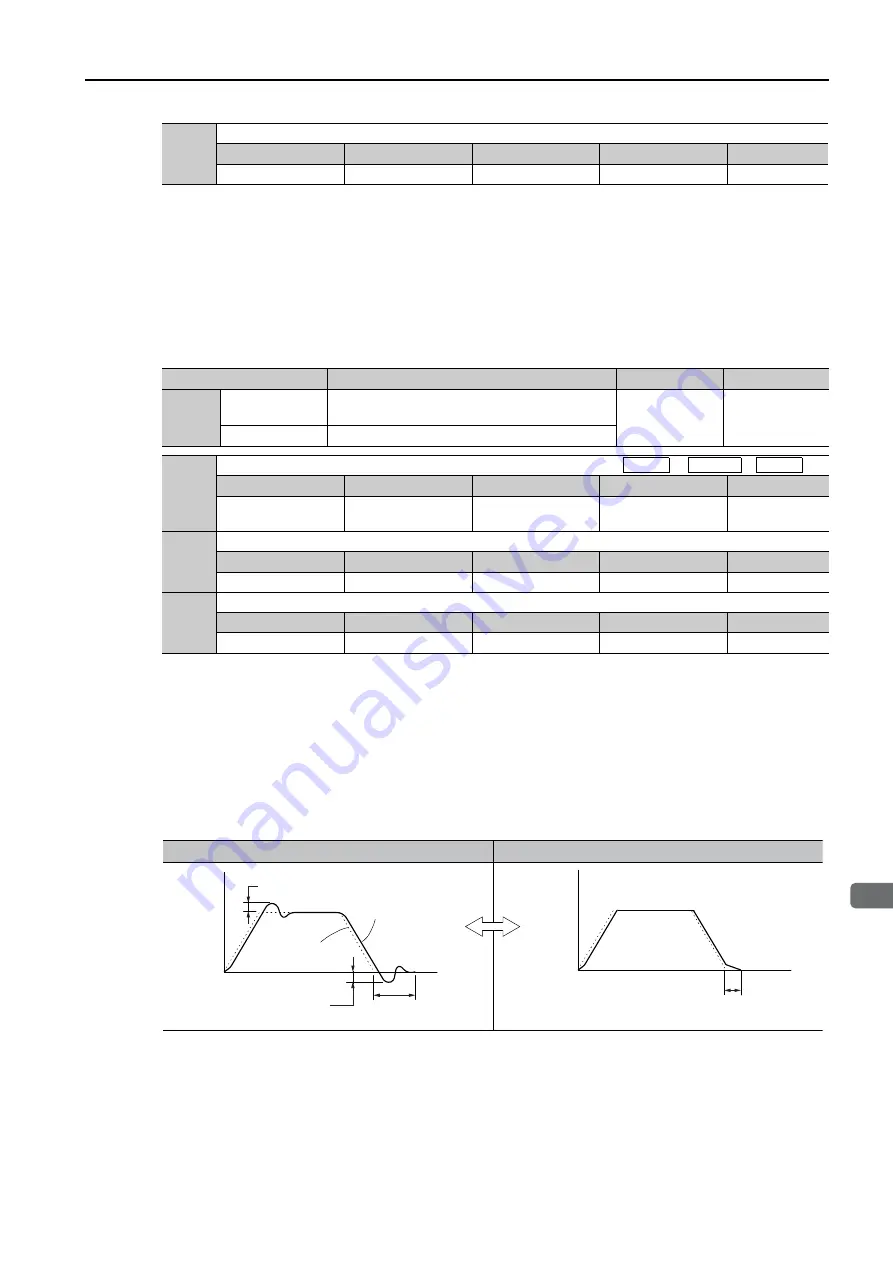

Mode Switching (Changing between Proportional and PI

Control)

You can use mode switching to automatically change between proportional control and PI con-

trol.

Overshooting caused by acceleration and deceleration can be suppressed and the settling time

can be reduced by setting the switching condition and switching levels.

Pn426

Torque feedforward average movement time

Setting Range

Setting Unit

Default Setting

When Enabled

Classification

0 to 5,100

0.1 ms

0

Immediately

Setup

Parameter

Meaning

When Enabled

Classification

Pn207

n.

0

(default setting)

Do not use V-REF.

After restart

Setup

n.

1

Use V-REF as a speed feedback input.

Pn300

Speed Reference Input Gain

Setting Range

Setting Unit

Default Setting

When Enabled

Classification

150 to 3,000

0.01 V/Rated

motor speed

600

Immediately

Setup

Pn307

Speed Reference Filter Time Constant

Setting Range

Setting Unit

Default Setting

When Enabled

Classification

0 to 65,535

0.01 ms

40

Immediately

Setup

Pn30C

Speed Feedforward Average Movement Time

Setting Range

Setting Unit

Default Setting

When Enabled

Classification

0 to 5,100

0.1 ms

0

Immediately

Setup

Speed

Position

Torque

Without Mode

S

witching

With Mode

S

witching

Motor

s

peed

Over

s

hooting

Actual

S

ervomotor

operation

Reference

Time

S

ettling time

Over

s

hooting

Motor

s

peed

S

ettling time

Time