model no.

060-1300-6

| contact us: 1.866.523.5218

model no.

060-1300-6

| contact us: 1.866.523.5218

79

TROU

bles

HOO

TING

model no.

060-1300-6

| contact us: 1.866.523.5218

PRObleM

POssIble CAUse

sOlUTION

Engine does not

start

Spark plug wire disconnected.

Reconnect wire.

Engine Throttle Control Lever incorrectly

set.

Put lever in START position.

Fuel tank empty.

Add fuel.

Choke control (if so equipped) in incorrect

position.

Move to CHOKE position.

Stale gasoline.

Drain fuel and add fresh fuel.

Dirty air filter.

Clean or replace filter.

Defective or incorrectly gapped spark plug. Inspect spark plug.

Carburetor out of adjustment.

Contact Technical Support Team.

Misadjusted throttle control.

Contact Technical Support Team.

Dirt or water in fuel tank.

Contact Technical Support Team.

Engine runs

poorly

Defective or incorrectly gapped spark plug. Inspect spark plug.

Dirty air filter(s).

Clean or replace.

Carburetor out of adjustment.

Contact Technical Support Team.

Stale gasoline.

Replace with fresh gasoline.

Dirt or water in fuel tank.

Contact Technical Support Team.

Engine cooling system clogged.

Clean air cooling system .

Engine overheats

Engine cooling system clogged.

Clean air cooling area.

Carburetor out of adjustment.

Contact Technical Support Team.

Oil level is low.

Check oil level.

Engine does not

shut off

Misadjusted throttle control or ignition

switch.

Contact Technical Support Team.

Wheels and tines

will not turn

Improper use of controls.

Review controls section.

Worn, broken, or misadjusted drive belt(s).

See “Checking and Adjusting

Forward Drive Belt Tension” or “Belt

Tension Adjustment”.

Internal transmission wear or damage.

Contact local dealer or the factory.

Bolt loose in transmission pulley.

Tighten bolt.

Tines turn, but

wheels don’t

Wheel Drive Pins not in WHEEL DRIVE.

See “Wheel Drive Pins”.

Bolt loose in transmission pulley.

Tighten bolt.

Internal transmission wear or damage.

Contact Technical Support Team.

Summary of Contents for 060-1300-6

Page 63: ...model no 060 1300 6 contact us 1 866 523 5218 63 PAGE INTENTIONALLY LEFT BLANK...

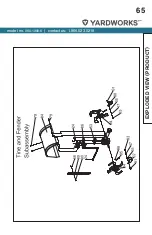

Page 65: ...model no 060 1300 6 contact us 1 866 523 5218 65 EXPLODED VIEW PRODUCT...

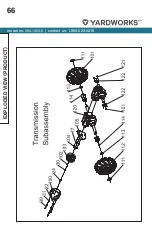

Page 66: ...model no 060 1300 6 contact us 1 866 523 5218 66 EXPLODED VIEW PRODUCT...

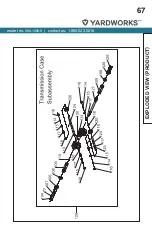

Page 67: ...model no 060 1300 6 contact us 1 866 523 5218 67 EXPLODED VIEW PRODUCT...

Page 73: ...model no 060 1300 6 contact us 1 866 523 5218 73 PAGE INTENTIONALLY LEFT BLANK...