31

18

Peak

Cap

Carriage Bolt

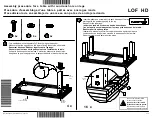

Fig. 13.3

Peak

Loop

A:

Insert Roof Peak Assembly in gap between Roof Panels. Peak Cap to be lined up with Rafter Corners. (fig.

13.1 and 13.2)

B:

Insert both Roof Peak Brackets through Carriage Bolt and attach Peak Loop to Carriage Bolt and twist to

tighten loosely.

C:

Loosely attach both Roof Peak Brackets to the Rafter Corners in the slotted holes with two #10 x 1-1/4” Pan

Screws as shown in fig. 13.3.

Fig. 13.1

Roof

Peak

Bracket

Roof Peak

Assemlby

Components:

2 x Roof Peak Brackets

Step 13: Attach Roof Peak to Roof Panels

x 3

Rafter

Corners

Rafter

Corners

Rafter

Corners

Fig. 13.2

Rafter

Corner

Roof

Peak

Bracket

#10 x 1-1/4” Pan

Screw x 2

Rafter

Corner

Rafter

Corner

Hardware

2 x #10 x 1-1/4” Pan Screw