Chapter 1 General

6. Piping Diagrams

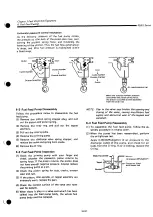

*4LHA Series

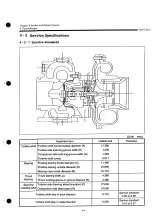

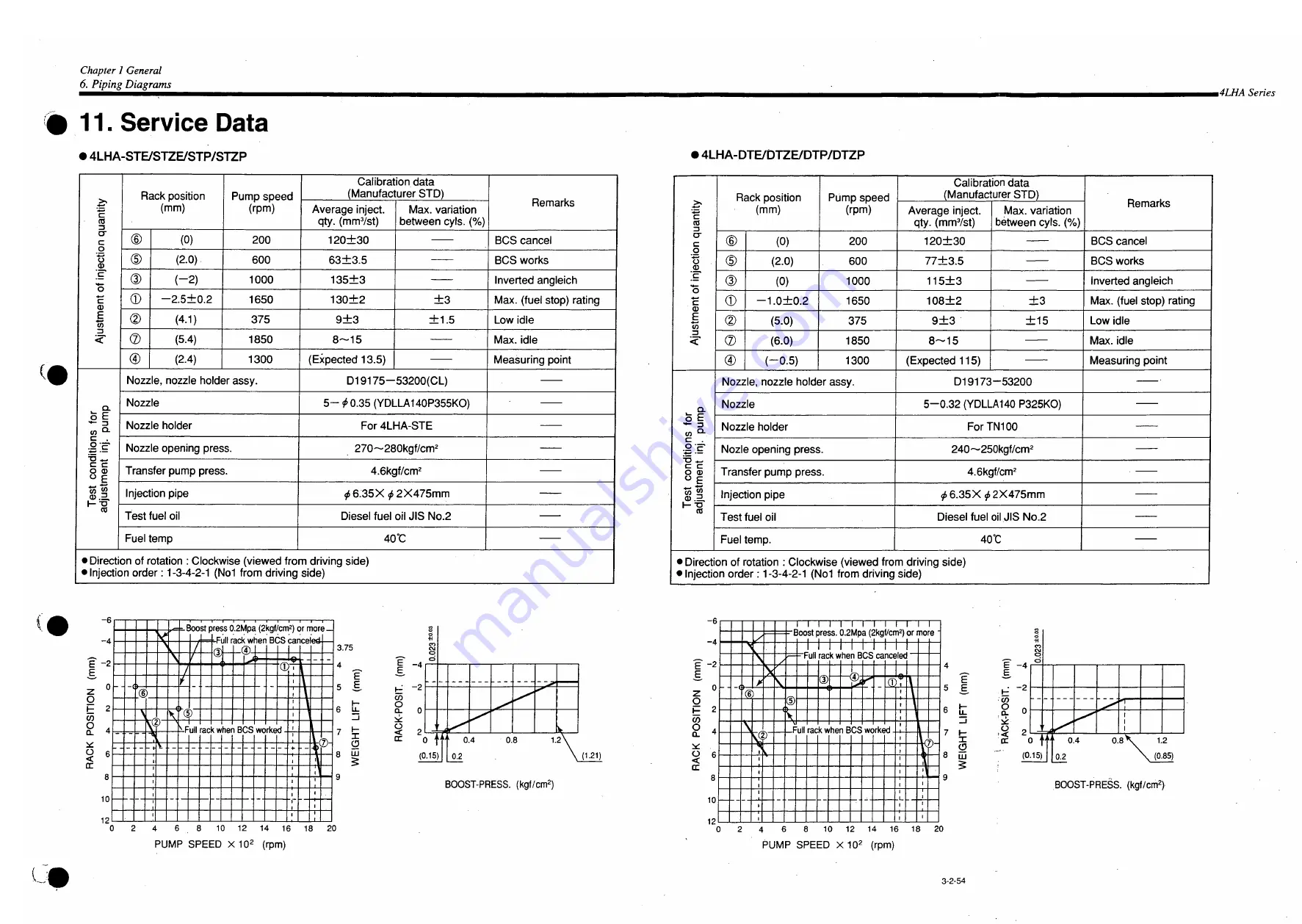

11. Service Data

• 4LHA-STE/STZE/STP/STZP

Ajustmen

t o

f injectio

n quantit

y

Rack position

(mm)

Pump speed

(rpm)

Calibration data

(Manufacturer STD)

Remarks

Ajustmen

t o

f injectio

n quantit

y

Rack position

(mm)

Pump speed

(rpm)

Average inject,

qty. (mm7st)

Max. variation

between cyls. (%)

Remarks

Ajustmen

t o

f injectio

n quantit

y

©

(0)

200

120±30

BCS cancel

Ajustmen

t o

f injectio

n quantit

y

(D

(2.0).

600

63±3.5

BCS works

Ajustmen

t o

f injectio

n quantit

y

(D

(-2)

1000

135±3

Inverted angleich

Ajustmen

t o

f injectio

n quantit

y

©

- 2 . 5 ± 0 . 2

1650

130±2

±3

Max. (fuel stop) rating

Ajustmen

t o

f injectio

n quantit

y

(4.1)

375

9 ± 3

±1.5

Low idle

Ajustmen

t o

f injectio

n quantit

y

®

(5.4)

1850

8~15

Max. idle

Ajustmen

t o

f injectio

n quantit

y

®

(2.4)

1300

(Expected 13.5)

Measuring point

Tes

t condition

s fo

r

adjustmen

t inj

. pum

p

Nozzle, nozzle holder assy.

D19175-53200(CL)

Tes

t condition

s fo

r

adjustmen

t inj

. pum

p

Nozzle

5 - ^ 0 . 3 5 (YDLLA140P355KO)

Tes

t condition

s fo

r

adjustmen

t inj

. pum

p

Nozzle holder

For 4LHA-STE

Tes

t condition

s fo

r

adjustmen

t inj

. pum

p

Nozzle opening press.

270~280kgf/cm

2

Tes

t condition

s fo

r

adjustmen

t inj

. pum

p

Transfer pump press.

4.6kgf/cm

2

Tes

t condition

s fo

r

adjustmen

t inj

. pum

p

Injection pipe

?

5 6.35X^2X475mm

Tes

t condition

s fo

r

adjustmen

t inj

. pum

p

Test fuel oil

Diesel fuel oil JIS No.2

Tes

t condition

s fo

r

adjustmen

t inj

. pum

p

Fuel temp

40°C

• Direction of rotation : Clockwise (viewed from driving side)

• Injection order: 1-3-4-2-1 (Not from driving side)

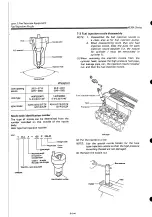

> 4LHA-DTE/DTZE/DTP/DTZP

Ajustmen

t of

injectio

n quantit

y

Rack position

(mm)

Pump speed

(rpm)

Calibration data

(Manufacturer STD)

Ajustmen

t of

injectio

n quantit

y

Rack position

(mm)

Pump speed

(rpm)

Average inject,

qty. (mmVst)

Max. variation

between cyls. (%)

Remarks

Ajustmen

t of

injectio

n quantit

y

©

(0)

200

120±30

BCS cancel

Ajustmen

t of

injectio

n quantit

y

©

(2.0)

600

77±3.5

BCS works

Ajustmen

t of

injectio

n quantit

y

©

(0)

1000

115±3

Inverted angleich

Ajustmen

t of

injectio

n quantit

y

©

—1.0±0.2

1650

108±2

±3

Max. (fuel stop) rating

Ajustmen

t of

injectio

n quantit

y

©

(5.0)

375

9 ± 3

±15

Low idle

Ajustmen

t of

injectio

n quantit

y

®

(6.0)

1850

8~15

Max. idle

Ajustmen

t of

injectio

n quantit

y

®

(-0.5)

1300

(Expected 115)

Measuring point

Tes

t condition

s fo

r

adjustmen

t inj

. pum

p

Nozzle, nozzle holder assy.

Dl 9173-53200

Tes

t condition

s fo

r

adjustmen

t inj

. pum

p

Nozzle

5-0.32 (YDLLA140 P325KO)

Tes

t condition

s fo

r

adjustmen

t inj

. pum

p

Nozzle holder

ForTN100

Tes

t condition

s fo

r

adjustmen

t inj

. pum

p

Nozle opening press.

240~250kgf/cm

2

Tes

t condition

s fo

r

adjustmen

t inj

. pum

p

Transfer pump press.

4.6kgf/cm

2

Tes

t condition

s fo

r

adjustmen

t inj

. pum

p

Injection pipe

^ 6 . 3 5 X ^ 2 X 4 7 5 m m

Tes

t condition

s fo

r

adjustmen

t inj

. pum

p

Test fuel oil

Diesel fuel oil JIS No.2

Tes

t condition

s fo

r

adjustmen

t inj

. pum

p

Fuel temp.

40°C

• Direction of rotation : Clockwise (viewed from driving side)

• Injection order: 1-3-4-2-1 (Not from driving side)

- 4

E - 2

E

0

2

4

6

8

10

12

CO

O

CL

o

<

-E loo

St f

iress 0.2Mpa (2kgf/cm

2

) or mor

f u l l m r \ f i u h a n D ^ C / - « o n ^ n l r w H

3 -

/

(E

i

3 -

\

(E

_

J

- -

f

/ -

-

- -

'©

-

-

\

'd

\

v

>- Pull

ac

f w h o

IB DS

WC

rk«

ac

IB DS

WC

rk«

f.

\

I)

r

r

3.75

4 _

E

5 £

6 t

8 UJ

E

E

co

O

a.

cr

BOOST-PRESS, (kgf/cm

2

)

2 4 6 8 10 12 14 16 18

PUMP SPEED X 10

2

(rpm)

20

-6

-4

E -2

E.

Z

0

O

i— 2

4

6

8

10

12

CO

O

a.

o

<

1 1 1 1 1 1 1 1 1 1 1 1 1

- t

JOOSI press, u.^mpd ^Kgi/cnr-; or nu re

v

I l i l l l i l l

\

/

- F

Ull

rac

KM

nen e

1

(Jb

ca nee 'iec

\

®

1

-- -(

\

®

f '

- (D

-- -(

tø

-

t

©

V

t

\

V

F Ull rac kw he

n Rr.fi WC

rkc

•d

\

\

f

Ull rac kw he

WC

rkc

K

D-

D-

1

'

:

i

-•

--

1

-•

--

1

i

E

5 E,

6 t

_ i

7 I—

I

CD

8

UJ

E

E

8

DC

-4

-2

0

o

-4

-2

0

o

-4

-2

0

o

-4

-2

0

o

0 f

(0.15)

0.4 0 . 8 \

0.2

1.2

\ (0.85)

BOOST-PRESS, (kgf/cm

2

)

2 4 6 8 10 12 14 16 18 20

PUMP SPEED X 10

2

(rpm)

3-2-54

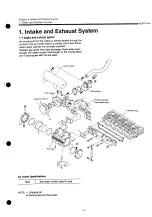

Summary of Contents for 4LHA-DTP

Page 79: ...Y00R4782 2 Fig fc GEAR HOUSING REFER TO F i g l REFER TO F i g 2 8 2 9 7 EFER TO Fi g 5 ...

Page 81: ...Y00R4782 FLYWHEEL HOUSING 4LHA STZE P 4LHA DTZE P 4LHA HTZE P 13 1 4 ...

Page 87: ...Y00R4782 LUB OIL S U M P 9 7 7 7 7 o 1 01 21 2 N 4LHA HTE P 4LHA HTZE P OPTIONAL 12 ...

Page 89: ...Y0OR4782 OIL SEAL HOUSING REFER TO Fig 1 ...

Page 101: ...Y00R4782 Fig j 2 RåV Tfc JI K S U C T I O N M A N I F O L D ...

Page 107: ...Y00R4782 Fig CAMSHAFT DRIVING GEAR ...

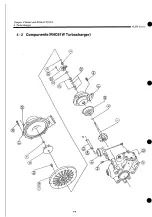

Page 109: ...Y00R4782 Fig 1 C e 4LHA ST Z E P I O TURBOCHARGER 4LHA ST Z E P REFER TO F i g 1 3 ...

Page 111: ...Y00R4782 r 1 ft t y 4LHA DT Z E P F i g l O TURBOCHARGER 4LHA DT Z E P REFER TO F i g 1 3 ...

Page 113: ...Y00R4782 1 7 fcf 4LHA HT Z E P Fig I I T U R B O C H A R G E R 4LHA HT Z E P ...

Page 115: ...Y00R4782 Fig 18 ftiB M I X I N G E L B O W E X H A U S T B E N D 5 ...

Page 117: ...Y00R4782 Fig 18 1 5 E W K M I X I N G E L B O W E X H A U S T B E N D 5 ...

Page 121: ...Y00R4782 Fig I W AIR COOLER 4 L H A H T E P 4 L H A H T Z E P REFER TO F i g 24 ...

Page 127: ...Y00R4782 F i g t C LUB OIL COOLER REFER TO F i g 1 9 FLYWHEEL SIDE ...

Page 131: ...Y00R4782 Fig 24 LUB OIL SYSTEM REFER TO Fi g 2 4LHA STZE P 4LHA DTZE P REFER TO Fi g 6 ...

Page 135: ...Y00R4782 Fig C O LUB OIL PIPE TURBOCHARGER REFER TO F i g 1 5 1 6 1 7 ...

Page 137: ...Y00R4782 Fig 27 MMM V LUB OIL PIPE COOLER REFER TO F i g 22 a 7 f O U T L O STRAINER OUT ...

Page 139: ...Y00R4782 Q Q m y7 m 4LHA ST DT Z E P Fi g O C S W P U M P 4LHA ST DT Z E P ...

Page 141: ...Y00R4782 OQ ymxy 4LHA HT Z E P Fi g fc 57 C S W P U M P 4LHA HT Z E P ...

Page 143: ...Y00R4782 Fig COOLING FRESH W A T E R P U M P REFER TO F i g 62 ...

Page 145: ...Y00R4782 Fig 31 mo z 4LHA ST DT Z E P C F W COOLER 4LHA ST DT Z E P 5 f fc f ui FLYWHEEL SIDE ...

Page 149: ...Y00R4782 Q Q mMW 4LHA STE DTE P Fi g O O C S W PIPE 4LHA STE DTE P REFER TO F i g 3 1 ...

Page 155: ...Y00R4782 g g nm uy m 4LHA HT Z E P C S W PIPE 4LHA HT Z E P REFER TO F i g 32 11 12 SIED PART ...

Page 157: ...Y00R4782 Fig o e nmiuy 4LHA ST DT Z E P O D C F W PI PE 4LHA ST DT Z E P ...

Page 159: ...Y00R4782 Fig Q 7 JMP W7 I 4LHA HT Z E P O f C F W PIPE 4LHA HT Z E P REFER TO F i g 2 3 ...

Page 161: ...Y00R4782 Fi g Q O C S W STRAINER OPTIONAL c s w PUMP KINGSTON C O C K ...

Page 167: ...Y00R4782 4 1 mmxyy 4LHA ST DT Z E P I FUEL INJECTION P U M P 4LHA ST DT Z E P ...

Page 173: ...Y00R4782 ...

Page 175: ...Y00R4782 ...

Page 177: ...Y00R4782 43 M t GOVERNOR ...

Page 179: ...Y00R4782 Å A JWD f Ktfxr Fig F U E L F E E D P U M P REFER TO Fig 41 ...

Page 187: ...Y00R4782 Fig A O rø W7 4LHA ST DT Z E P H O FUEL PIPE 4LHA ST DT Z E P ...

Page 189: ...Y00R4782 Fig A Q miUy 4LHA ST DT Z E P f O FUEL PI PE 4LHA ST DT Z E P ...

Page 193: ...Y00R4782 Fig C n B7 f 4LHA ST DT Z E P U U FUEL STRAINER 4LHA ST DT Z E P ...

Page 195: ...Y00R4782 Fig K 1 TO7 i 4LHA HT Z E P w I FUEL STRAINER 4LHA HT Z E P REFER TO F i g 12 ...

Page 197: ...Y00R4782 Fig 52 OIL WATER SEPARATER OPTIONAL 19 mv t 9 14 F R O M FUEL TANK ...

Page 203: ...Y00R4782 F i g O O P O W E R STEERING P U M P C F W P U M P ...

Page 205: ...Y00R4782 Fig UU P O W E R S T E E R I N G C O O L E R T A N K 1 6 ...

Page 207: ...Y00R4782 57 ATFA f Fig O I ATF PIPE REFER TO F i g 5 6 FER TO F i g 5 5 ...

Page 211: ...Y00R4782 Fifl W O STARTING MOTOR REFER TO F i g 3 ...

Page 213: ...Y00R4782 GENERATOR REFER TO Fig 2 ...

Page 215: ...Y00R4782 Fig D I GENERATOR OPTIONAL REFER TO F i g 30 REFER TO F i g 60 ...

Page 221: ...Y00R4782 Fl g O O SENSOR MOUNT ...

Page 223: ...Y00R4782 H E A T E R P L U G O P T I O N A L 4 L H A H T E P 4 L H A H T Z E P ...

Page 225: ...Y00R4782 Fig OO I N S T R U M E N T P A N E L B T Y P E O P T I O N A L ...

Page 227: ...Y00R4782 Fig NSTRUMENT PANEL C TYPE OPTIONAL ...

Page 229: ...Y00R4782 66 Fig OO I N S T R U M E N T P A N E L C T Y P E O P T I O N A L ...

Page 231: ...Y00R4782 Fig 67 4 0 INSTRUMENT PANEL D TYPE OPTIONAL ...

Page 233: ...Y00R4782 Fig 67 N S T R U M E N T P A N E L D T Y P E O P T I O N A L ...

Page 235: ...Y00R4782 Fig 6 8 T O O L ...

Page 237: ...Y00R4782 Fig D Ø GASKET SET OPTIONAL 1 A ...

Page 302: ...Example of setup with HSW630A1 Hurth marine gear WATER INLET IS M l o 3 0 WATER INLET 2 3 ...

Page 303: ...Chapter 1 General 5 Dimensions i4LHA Series 4LHA STZE STZP 9 96 XVW 9 06 um 1 18 ...

Page 305: ...Chapter 1 General 5 Dimensions 4LHA Series 4LHA DTZE DTZP 9 96 XVW g oe nm 1 20 ...

Page 307: ...Chapter 1 General 5 Dimensions i4LHA Series 4LHA HTZE HTZP g 96 xvw S06NIW 1 22 ...

Page 317: ...Chapter 1 General 7 Electrical Diagrams m4LHA Series 4LHA STZE 1 30 ...

Page 318: ...Chapter 1 General 7 Electrical Diagrams 4LHA Series 4LHA DTZE 1 32 ...

Page 319: ...Chapter 1 General 7 Electrical Diagrams 4LHA Series 4LHA HTE HTZE Eng stop solenoid 1 33 ...

Page 473: ...Chapter 3 Fuel Injection Equipment 9 Tools 4LHA Serie t 3 2 51 ...

Page 507: ...Chapter 5 Lubrication System 1 Lubrication System 4LHA Serie 1 1 Construction ...

Page 519: ...Chapter 6 Cooling Water System 1 Cooling Water System 4LHA Series Cylinder block ...