STARTER MOTOR

10-18

3TNV88F Service Manual

Starter Motor

No-load Test

Test the characteristics of the starter motor by

performing a no-load test.

NOTICE

The starter motor can be damaged if operated

continuously longer than 10 seconds while

performing the no-load test.

1. Secure the starting motor in a vise or other

suitable fixture.

2. Connect an ammeter

(Figure 10-35, (1))

in

series between the battery positive (+) terminal

and the main positive (+)

terminal

(Figure 10-35, (3))

on the starter

motor.

Note: The ammeter and all wire leads used in

this test must have a capacity equal to or

greater than the amperage draw

specification for the starter motor being

tested.

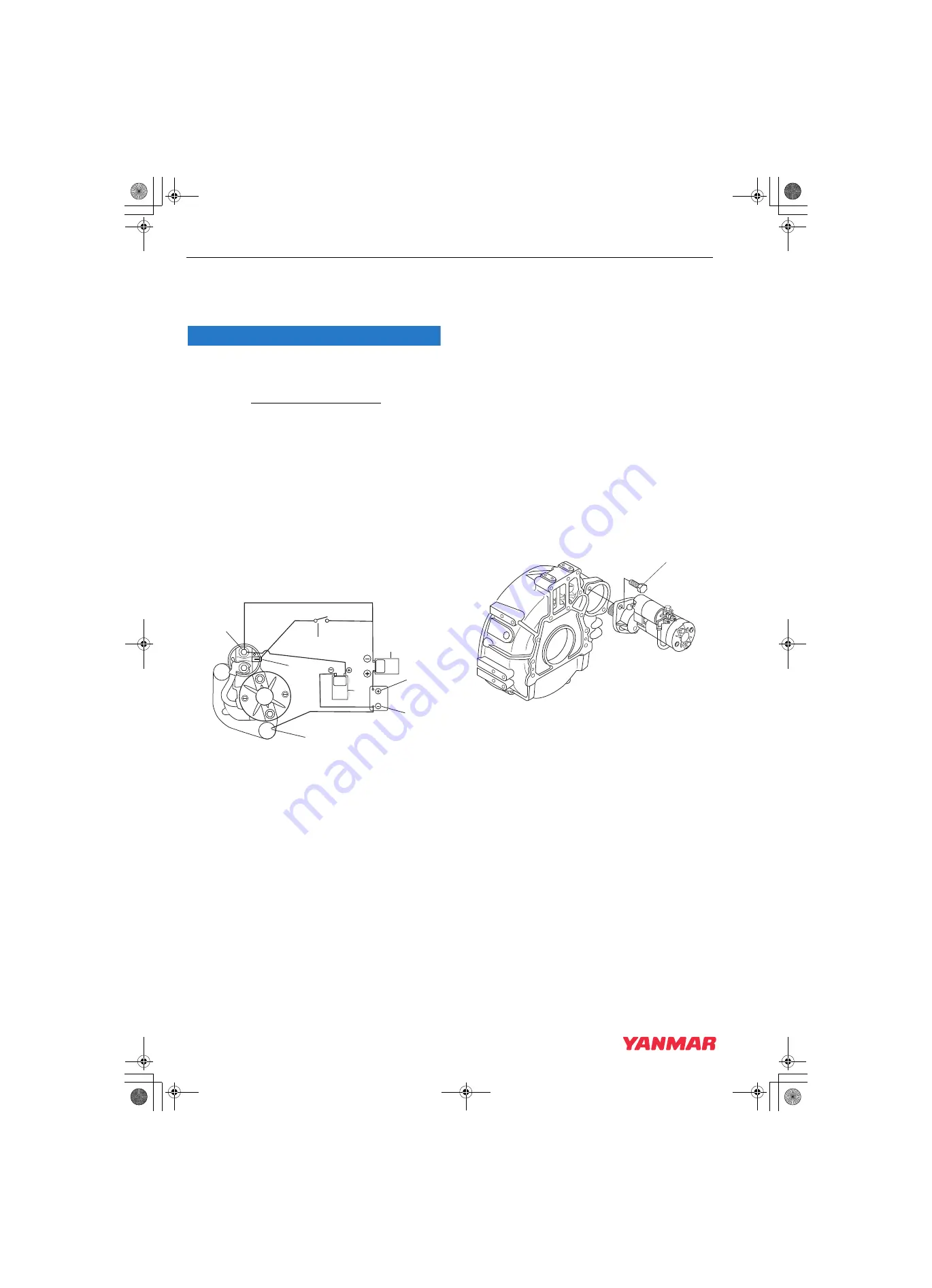

Figure 10-35

3. Connect a wire lead between the mounting

base of the starter motor

and the battery negative terminal

.

4. Connect a voltmeter

(Figure 10-35, (7))

to the

battery negative (-) terminal

and the main positive (+) battery terminal

on the starter motor.

5. Install a switch

in a circuit

between the battery positive (+) terminal

(Figure 10-35, (2))

and the starter magnetic

switch (solenoid) terminal

on the starter motor.

6. Use a suitable tachometer to monitor the rpm of

the starter.

7. Turn the switch to the ON position. Monitor the

rpm, amperage draw and voltage. For test

specifications,

see

for the appropriate starter motor.

Installation of Starter Motor

1. Reinstall the starter motor to the flywheel

housing.

2. Reinstall the starter mounting bolts

(Figure 10-36, (1))

. Tighten the bolts to

specification.

Standard Bolts and Nuts on page 4-25

.

Figure 10-36

3. Reconnect the electrical wires to the magnetic

switch assembly (solenoid). Be sure to place

the cover over the battery positive (+) cable

connection.

4. Reconnect the battery cables at the battery.

M

8

3

6

1

2

5

7

4

K0002127A

1

K0002126

3TNV88F_SVM_A4.book 18 ページ 2012年7月26日 木曜日 午後6時4分