FAILURE DIAGNOSIS

1-136

TNV DI Service Manual

Method and Procedure of Failure Diagnosis

Analog Input Related Failures

Rack position sensor

Related DTC

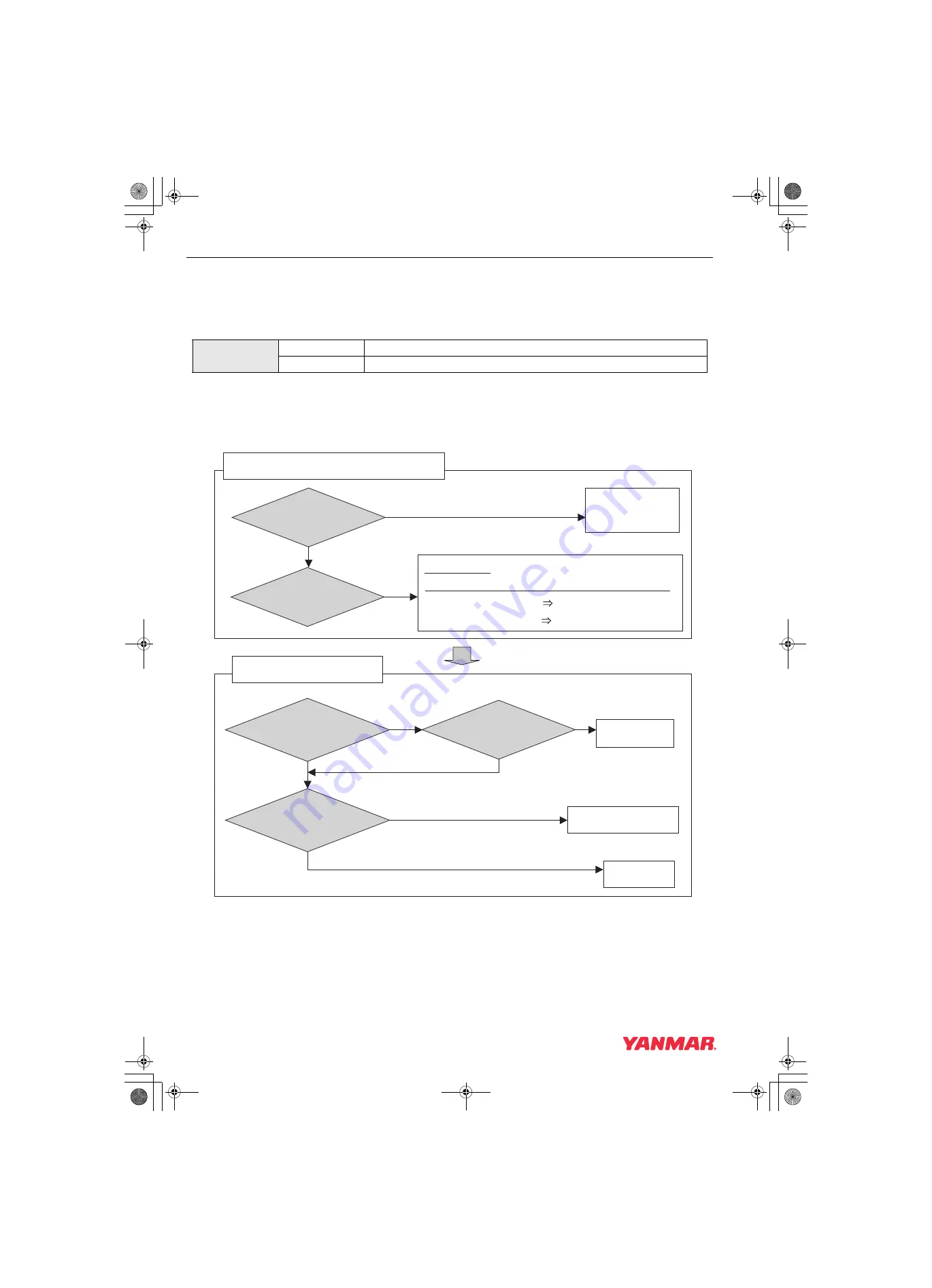

Work flow

*For details of the work, see after-mentioned "<Diagnosis Description>."For the operation of the

diagnosis tool, see “Diagnosis tool Operation Manual” separately.

DTC

P1202/4

Rack Position Sensor Error (Low Voltage)

P1203/3

Rack Position Sensor Error (High Voltage)

017534-00E

Replace the

E-ECU.

Replace the

fuel injection pump.

Replace the

harness.

OK

OK

OK

NG

NG

NG

1. Input voltage check

of the rack position sensor

(h E-ECU)

2. Check the harness

continuity.

3. Execution of

directive rack position control

(use diagnosis tool)

A. Check the current

failure display.

B. Check the detected

value to estimate the

cause of failure.

DTC in the failure history indication

Check the failure

conditions.

Current failure

exists.

Initial diagnosis with the diagnosis tool

Failure diagnosis flow

[Check items]:

Rack position sensor voltage (AD value) - "Signal Data (SD)"

• SD=0 (0V) or equivalent

Signal wire disconnected ?

• SD=5000 (5.0V) or equivalent

Sensor GND wire disconnected ?

TNV_DI_SM_A4-Troubleshooting.book 136 ページ 2007年11月15日 木曜日 午後5時27分