20

10. MAIN BODY SPECIFICATION

10.1 MAIN SPECIFICATIONS

■

NDP-5 series

Type

NDP-5

FAT FST FPT FVT FDT

Nominal Diameter

1/4

˝

(6 mm)

Fluid

Connection

Suction Port

Rc 1/4

NPT 1/4

Discharge

Port

Air

Connection

Supply Port

Rc 1/4

NPT 1/4

Exhaust Port

Rc 3/8

NPT 3/8

Operating Air Pressure

0.2-0.7 MPa

0.2-0.7 MPa *

1

Maximum Discharge

Pressure

0.7 MPa

0.7 MPa *

1

Discharge Volume/cycle*

2

20 mL

Maximum Discharge Volume

11 L/min

Maximum Air Consumption

250 L/min(ANR)

Slurry Limitation

Limitation of Viscosity

0.1 Pa•s or less

Operating

Temperature

Range

Temperature

Ambient

0-70

˚

C

Temperature

Liquid

0-100

˚

C

0-60

˚

C

A-weighted emission sound

pressure level*

4

81 dB

80 dB

A-weighted sound power

level*

5

92 dB

90 dB

Weight

1.6 kg

2.7 kg

1.3 kg

1.7 kg

1.4 kg

■

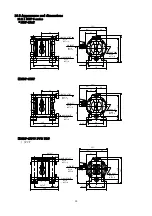

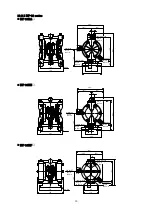

DP-10 series

Type

DP-10

BA

□

BS

□

BA

□

-D BS

□

-D BP

□

Nominal Diameter

3/8

˝

(10 mm)

Fluid

Connection

Suction Port

Rc 3/8

NPT 3/8

φ

17.3 O.D.

Rc 3/8

NPT 3/8

Discharge

Port

Rc 3/8

Air

Connection

Supply Port

Rc 1/4

NPT 1/4

Rc 1/4

Rc 1/4

NPT 1/4

Exhaust Port

Rc 3/8

NPT 3/8

Rc 3/8

Rc 3/8

NPT 3/8

Operating Air Pressure

0.2-0.7 MPa

0.2-0.7 MPa *

1

Maximum

Discharge Pressure

0.7 MPa

0.7 MPa *

1

Discharge Volume/cycle*

2

50 mL

Maximum Discharge Volume

20 L/min

18 L

/

min

17 L/min

Maximum Air Consumption

300 L/min(ANR)

250 L/min(ANR)

Slurry Limitation

1 mm or less

Limitation of Viscosity

0.5 Pa•s or less

Operating

Temperature

Range

Temperature

Ambient

0-70

˚

C

Temperature

Liquid

Diaphragm materials

NBR/CR

: 0-70

˚

C

TPEE/EPDM

: 0-80

˚

C

FKM/TPO/PTFE :

0-100

˚

C

0-60

˚

C

A-weighted emission sound

pressure level*

4

84 dB

82 dB

A-weighted sound power

level*

5

92 dB

93 dB

Weight

3.5 kg

5.2 kg

4.5 kg

6.2 kg

3.0 kg

*1. Maximum air pressure for non-metallic pumps decreases with temperature (See 21 page of Temperature

Pressure Curve).

*2. Discharge Volume/cycle is highly dependent on application. Contact your local distributor or Yamada for

more information.

*3. Do not use the flat valve type pump for the liquids with slurry.

*4. The measuring method is based on ISO 1996.

*5. The measuring method is based on ISO 3774.