10

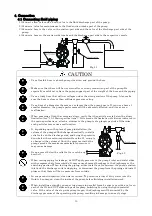

3. Installation

3.1 Method of transport

• When lifting the pump using a chain hoist or crane before transporting it, be sure to lift it by the

specified lift point (see “1. Names of parts and materials”).

WARNING

• Be careful that nobody will pass under the pump when you lift it. It would be very dangerous

if the pump should fall.

CAUTION

• See “10.1 Main specifications”. Remember that the pump is heavy, so extreme care must be

taken when lifting it.

• When moving the pump with a forklift or truck, make sure that the pump will not fall. If it

does, it may be damaged and/or cause bodily injury.

• NEVER try to move the pump by pulling the hose connected to the pump. The hose or the

pump may be damaged.

3.2 Installing the pump

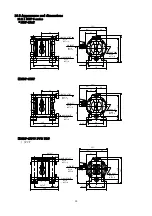

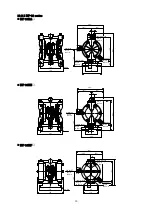

1) Decide where the pump should be installed and secure

a suitable space (see Fig. 3.1 A to D).

<NOTE>

• Try to keep the suction lift as short as possible.

To protect diaphragm from abnormal breakage, inlet pressure must be

kept below the following values:

*PTFE diaphragm

:0.02 MPa (height 2 m) During operation

:0.05 MPa (height 5 m) Not in operation

*Other diaphragms

:

0.1 MPa (height 10 m)

(Condition with fresh water under ambient temperature)

• Remember to provide sufficient space around the pump for

maintenance.

• The direction of the fluid intake port and the discharge port can be

switched opposite from each other.

(For switching, see the maintenance manual.)

• In the event diaphragm failure the exhaust from pump may contain

some sludge.

When operating the pump where it would have an impact on the

environment, the exhaust should be directed to a place where there

will be no environmental impact.

2) Remove the pump from the package and

install it in the designated location.

3) When fixing the pump in place, use the

cushions on the pump base, and secure the

pump by tightening the tied

-

down bolts a

little at a time.

Fig.3.1