7

Inspection and maintenance

07.2020

135

ba

-o

.2

.6

.0

-us

-3

.2

-ys

|

A1

18

67

50

1 Re

v A

E

Loop formations

➢

Replace wire ropes with loop formations.

Local increase of the rope diameter

➢

Replace wire ropes with the following local rope diameter increases.

≤ 5

% with wire ropes with steel core

≤ 10

% with wire ropes with fibre core

Flattening

➢

Check wire ropes with flattening daily and replace if necessary.

Kinks or tightened rope loops

➢

Replace wire ropes with kinks or tightened rope loops.

Bends

➢

Replace wire ropes with severe bends.

Damage due to the effects of heat or arcs

➢

Replace wire ropes with bluish discolouration or broken or melted wires.

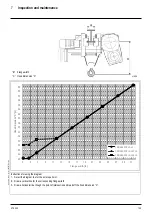

Wire breakages

➢

Relieve the rope tension and bend the rope roughly by hand to the radius of the rope

pulley.

➢

Compare visible wire breakages with the number of wire breakages permitted (see

rope certificate) and replace if necessary.

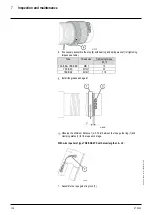

Twist formation

Wire ropes must be checked daily for twist formations.

➢

Travel to the highest and lowest hook position without a load.

➢

With visible twist formations, untwist the wire rope (see section 4.13

Rope

reeving

and the section section

Discarding a wire rope

).