4

Installation

07.2020

39

ba

-o

.2

.6

.0

-us

-3

.2

-ys

|

A1

18

67

50

1 Re

v A

E

Trolley types OE-S06 - OE-S07

Trolley types OE-S06 - OE-S07

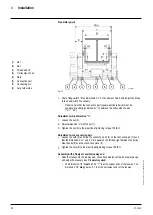

Hook position

Eccentric position

X

Hook

position

Eccentric

[in]

1.5...1.59

1

A

1.61...1.79

C

1.81...1.99

2

A

2.01...2.19

C

2.2...2.38

3

A

2.4...2.58

C

2.6...2.78

4

A

2.8...2.97

C

2.99...3.17

5

A

3.19...3.37

C

3.39...3.56

6

A

3.58...3.76

C

Fig. 31

Fig. 32

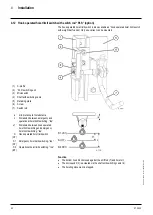

•

Unscrew fixing elements (1 + 2)

•

On OE-S07 4PD, the pieces of two units are supplied loose (please unscrew as

required).

•

Remove hook (3)

•

Rotate hook by180° (OE-S04)

•

Insert adjusting screws (S) in the hook position determined from the table.

•

Position eccentric plates (4) in slot as specified by the table.

•

Tighten fixing elements (1 + 2) finger-tight.

Fig. 33 Fig. 34

Horizontal adjustment:

Fig. 35

Pos

OE-S04 -OE-S05 OE-S06 - OE-S07

[in]

[in]

Z

≥

0.39

≥

0.59

Y

≥

1.18

≥

1.18

1.

Adjust final hook position according to Fig. and table.

2.

Tighten fixing elements (1) and (2) with tightening torque

M10 = 38 lb

f

ft

.

NOTICE

Malfunction hazard.

In the event of a fault, e.g. trolley running into the runway end

stops unchecked, broken rope, all elements of the anti-jump catch must be checked

immediately for damage/faults and completely replaced if necessary. The functional

reliability of the system must be ensured.