4

Installation

28

07.2020

ba

-o

.2

.6

.0

-us

-3

.2

-ys

|

A1

18

67

50

1 Re

v A

E

Preparatory work

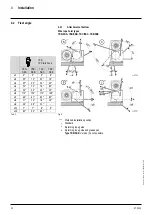

(1) Nut

(2) Nut

(3) Threaded bolt

(4) Trolley side cheek

(5) Nuts

(6) Connection part

(7) Connecting pin

(8) Axle holder side

Fig. 14

Check

flange width “B” and dimension “c” on the basis of Tab. 9 and adjust the trolley

to the beam width if necessary.

–

Observe here that the connection part (square-section tube) (6) must be

positioned centrally (to dimension “c”) between the trolley side cheeks

(“e1”

=

“e2”).

Adjustment work, dimension “c”:

Loosen the nut (2).

Adjust dimension “c” with the nut (1).

Tighten the nut (2) to the prescribed tightening torque 159 lb

f

ft.

Adjustment work, connection part:

Loosen the nuts (5) and slide the connection part (6) on the connecting pin (7) such

that the dimensions “e1” and “e2” are equal on the left and right between the trolley

side cheeks (4) and the connection piece (6).

Tighten the nuts (5) to the prescribed tightening torque 159 lb

f

ft.

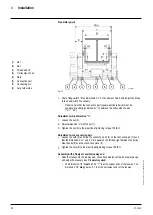

Assembly with a freely accessible runway end

Slide the trolley onto the runway end, check track clearance f/2 with a feeler gauge

and adjust if necessary (see

Preparatory work

).

–

The dimension “f/2”

must

be 0.02

+0.04

in at the widest point of the runway. The

dimension “f/2”

may

be max. 0.1 in at the narrowest point of the runway.