4

Installation

07.2020

69

ba

-o

.2

.6

.0

-us

-3

.2

-ys

|

A1

18

67

50

1 Re

v A

E

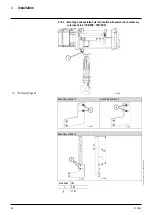

Assembly position 5

Dimension [in]

d

3.58

e

4.84

The arrow in the figure shows the contact area.

Type

Trolley type

Reeving

Drum length

Assembly

position

YKA/SKA

OE-S04

2PS, 4PS

L2 + L3

1

YKB/SKB

OE-S04

2PS, 4PS

L2 + L3 + L4

1

YKC/SKC

OE-S05

2PS, 4PS

L2 + L3 + L4

1

OE-S06

YKE/SKE

OE-S06

2PS

L2 + L3 + L4 + L5

2

1)

OE-S07

4PS

L2 + L3 + L4 + L5

4

YKD/SKD

OE-S06

2PS

L2

3

1)

L3 + L4 + L5

5

4PS

L2 + L3 + L4 + L5

3

1)

1)

Observe the assembly position of the screws.

Observe the mounting position of the screws.

Fasten the “

PL

S” (1) switching unit on at the prescribed position with the bolted

connections, see figures above.

Tighten the bolted connections with the prescribed tightening torque (12 Nm).

Perform a functional test, see the

Performing a functional test

section

Perform the functional test

Move the operational limit switch (B

) to the top.

–

Movement stops.

Actuate the override button “S260” on the control box and the UP button at the same

time until the hoisting movement stops.

–

No more upward movement is possible.

Actuate the DOWN button.

–

If a downwards movement is possible, the “PLS”

switching unit has tripped.

–

If no downwards movement is possible, then the emergency limit switch has

tripped. In this case the “PLS” switching unit must be adjusted anew.