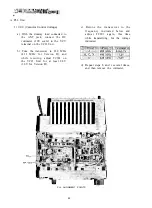

Alignement

r

The high reliability of the chip components

in the FT-712RH m i n i m i z e the possibility

that repair or realignment should be needed

after leaving the factory. However, if

damage occurs and some parts subsequently

be replaced, realignment may be required.

If a sudden problem occurs during normal

operation, it is likely due to component

f a i l u r e ; r e a l i g n m e n t should not be done

u n t i l after the faulty component has been

replaced.

Because of the compact circuitry of this

transceiver, we recommend that servicing be

performed only by authorized Yaesu service

technicians who are experienced with the

circuitry and fully equipped for repair and

alignment. Therefore, if a fault is suspected,

contact the dealer from whom the transcei-

ver was purchased for instructions regarding

repair. Authorized Yaesu service technicians

realign all circuits and make complete per-

formance checks to ensure compliance with

factory specifications after replacing any

faulty components.

Those who do undertake any of the follow-

ing alignments are cautioned to proceed at

their own risk. Yaesu must reserve the

r i g h t to c h a n g e circuits and alignment

p r o c e d u r e s in the interest of improved

performance, without notifying owners.

No alignment should be attempted unless

the normal function and operation of the

t r a n s c e i v e r are clearly understood, the

cause of the malfunction has been clearly

p i n p o i n t e d and any faulty components re-

placed, and the need for realignment deter-

mined to be absolutely necessary.

The following test equipment (and thorough

familiarity with its correct use) is necessary

f o r complete realignment. Correction of

problems caused by misalignment resulting

from use of improper test equipment is not

covered under the warranty policy.

A 50-ohm dummy load that is non-reactive

up to 500 MHz is required. Correct align-

ment is not possible with an antenna.

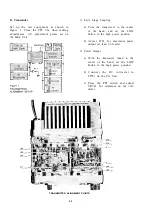

Alignment Equipment

DC voltmeter (at least 20-kilohms/volt)

500 MHz standard signal generator (SSG)

with calibrated level and modulation (see

note below)

AF signal generator

SINAD meter (SINADDER)

FM linear detector (deviation meter)

CM coupler (directional coupler)

RF wattmeter (50W, ±5% @ 500MHz)

50-ohm non-reactive (@500 M H z ) dummy

load

Frequency counter ( l O O H z resolution at

500MHz)

Oscilloscope (recommended, not required)

Note: SSG levels referred to in the align-

ment procedure are based on OdBu=0.5uV.

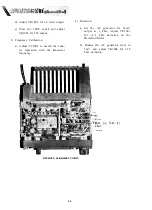

Alignment Precautions

Correct alignment requires that the ambient

temperature be the same as that of the

transceiver and test equipment, and that

this temperature be held constant between

20 and 30 °C (68 to 86 °F). When the trans-

ceiver is brought into the shop it should be

allowed at least 2 hours for thermal equal-

ization before alignment.

Alignments must not be made unless the

oscillator shields and circuit boards are

firmly affixed in place. Also, the frequency

c o u n t e r must be thoroughly warmed up

before beginning.

Supply voltage during alignment must be

held constant at 13.8V DC. Use a well regu-

lated, adjustable power supply capable of at

least 10A continuous load.

23

Summary of Contents for FT-712RH

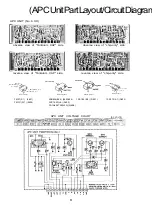

Page 4: ...PA UNIT APC UNIT 430 VCO UNIT LCD UNIT CONTROL UNIT BOARD LAYOUT 2...

Page 8: ...reverse view of chip only side 6...

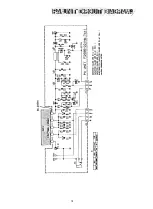

Page 9: ...MAIN UNIT VOLTAGE CHART DC VOLTS MAIN UNIT 1C VOLTAGE CHART DC VOLTS...

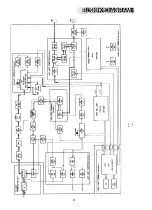

Page 15: ...20 32 HD404418A01F 02003 obverse view of 1C side 14...

Page 16: ...S obverse view of 1C side 15 ANODE 1 CATHOOE 1...

Page 17: ......

Page 18: ...PA UNIT No 7 XX obverse view of component side reverse view of component side 17...

Page 19: ...obverse view of chip only side reverse view of chip only side 18...

Page 20: ...19...

Page 21: ...MAIN UNIT 20...

Page 22: ...21 e s A...

Page 23: ...22...