9

4.

Wiping the tip on a high sulfur content, dirty or dry sponge.

5.

Contact with organic substances such as plastic, resin, silicone, grease and other

chemicals.

6.

Impurities in the solder and/or low tin content.

CARE OF TIPS

CAUTION

: The soldering, desoldering irons can reach very high temperature. Be sure to

turn the unit off prior to carrying out any maintenance or trouble shooting steps listed

below!

IMPORATNT:

Remove the tip and clean after each moderate to heavy use or daily for light usage. Remove

any loose build up in the tip retaining assembly to prevent tip freezing.

Both solder, desolder tips supplied are iron clad copper and if used properly should

maintain optimum life.

1. Always tin the tip before returning it to the holder, turning off the station, or storing it

for long periods of time. Wipe the tip on a brass cleaner prior to use.

2. Keeping the iron set at high temperatures (more than 400

℃

or 750

℉

) will shorten tip

life.

3. Do not use excessive pressure on the tip or rub the joint with the tip while soldering

and/or desoldering; it does not improve the heat transfer and may damage the tip.

4.

Apply solder to the joint, not the tip when soldering. The flux is naturally caustic and

thus will eat away the tip.

5.

Never clean the tip with a file or abrasive materials.

6.

Do not use fluxes which contain chloride or acid. Use only rosin or resin activated

fluxes.

7.

If an oxide film forms, it can be removed by careful buffing with 600-800 grit emery

cloth, isopropyl alcohol or equivalent and then the tinned areas with rosin-core solder

after the resin-core has melted.

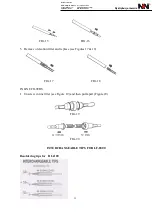

NEW TIPS

Applying the following steps give the tip optimum life.

1.

Set both temperature to min. then turn the main power switch to the “ON” position.

2.

Set soldering tip temperature to 250

℃

(500

℉

approx.) and desoldering tip

temperature to min. Coat the tinned surfaces with rosin-core solder after reaching 250

℃

.

3.

Set to the desired temperature about 3 minutes after being warmed that the station will

be ready for sue once it reaches preset temperature.

IMPORTANT: Remove and clean the tip daily. If a new tip is installed, remove any loose

build up in the barrel assembly, otherwise the tip may fuse to the heating element or

retaining barrel.

METHOD TO CHECK FOR LOSS OF SUCTION

The following procedures should be used on LF-8800 to check whether loss of suction is

Dystrybucja i serwis

Dane kontaktowe:

NDN - Zbigniew Daniluk

ul. Janowskiego 15

02-784 Warszawa

tel.: (22) 641-15-47

e-mail: [email protected]

NIP: 521-044-00-73