Check

Explanation/Comment

Always run piping to the pump.

Do not move pump to pipe. This could make final

alignment impossible.

Check that the suction and discharge piping are

supported independently near the pump and properly

aligned.

This helps to avoid strain on the pump when the flange

bolts are tightened.

Check that pipe hangers or other supports are installed.

Place supports at necessary intervals.

Check if expansion joints are installed correctly.

When expansion joints are used in the piping system,

they must be installed beyond the piping supports

closest to the pump. Tie bolts should be used with

expansion joints to prevent pipe strain. Do not install

expansion joints next to the pump or in any way that

would cause a strain on the pump resulting in system

pressure changes.

Check that pipe size is larger at pump connections.

It is usually advisable to increase the size of both suction

and discharge pipes at the pump connection to decrease

the loss of head from friction.

Install piping as straight as possible to avoid unnecessary

bends.

Use 45 degree or long sweep 90 degree fitting to

decrease friction losses.

Make sure that all piping joints are air tight.

Where flanged joints are used, assure that inside

diameters match properly.

Do not “spring” piping when making any connections.

Provide for pipe expansion when hot fluids are to be

pumped.

4.3.2 Suction piping checklist

The sizing and installation of the suction piping is extremely important. It must be selected

and installed so that pressure losses are minimized and sufficient liquid flows into the

pump when it is started and operated. Many NPSH problems can be directly attributed to

improper suction piping systems.

Piping checklist

Check

Explanation/comment

Checked

Keep the suction piping short in length, as

direct as possible, and never smaller in

diameter than the pump suction opening.

If the suction pipe is short, the pipe diameter can be

the same size as the suction opening. If longer suction

piping is required, pipes should be one or two sizes

larger than the opening depending on piping length.

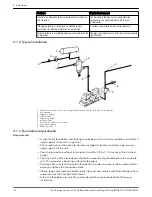

Check that the elbows in the suction piping

for horizontal double-suction pumps are

installed per the Hydraulics Institute

Standards since there is always an uneven

turbulent flow around an elbow.

When there is an elbow in a position other than the

vertical when in relation to the pump suction nozzle,

this causes more liquid to enter one side of the

impeller than the other. The result is highly

unequalized thrust loads that overheat the bearings

and cause rapid wear, which adversely affects the

hydraulic performance. See the Example of

unbalanced loading figure.

Check that pipe reducers on the inlet side

have no more than one pipe diameter

reduction in a single reducer.

This avoids excessive turbulence and noise.

When operating on a suction lift, check that

the suction pipe slopes upward to the

pump nozzle.

A horizontal suction line must have a gradual rise to

the pump. Any high point in the pipe can become

filled with air and prevent proper operation of the

pump.

4 Installation

G&L Pumps Series A-C 8100 Base Mounted Centrifugal Pump INSTRUCTION MANUAL

21