NEEDLE VALVE INSPECTION

If foreing matter is caught between the valve seat and the

needle.the gasoline will continue flowing and casue it to

overflow.if the seat and needle are worn out beyond the

permissible limits.similar trouble will occur.conversely.

if the needle sticks.the gasoline will not flow into the float

chamber.remove the carburetor.float chamber and floats.

and clean the float chamber and float parts with gasoline.if

the needles is worn as shown below.replace it together with

a valve seat.clean the fuel passage of the mixing chamber

with compressed air.

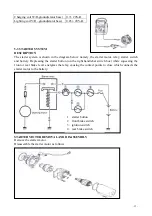

DIAGNOSIS OF CARBURETOR

Whether the carburetor is producing a proper mixture of fuel and air can be checked by making a

road test (simulating tue way the user operates the machine)with a standard spark plug fitted to the

engine.after the road test.remove the spark plug.and observe the appearance of the plug as well as

the surface of the piston crown.the color observed tells whether the mixture is too rich or too

lean.when replacing the spark plug.

MIXTURE ADJUSTMENT

●

This adjustment is effected mainly by main jet and jet needle.

Before doing so.check to be sure that the float level is correctly set and that the overflow

pipe.vacuum hose.inlet hose and air cleaner are in sound condition.

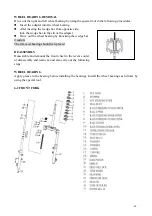

●

Find out at which throttle position the engine lacks power or otherwise performs poorly.drive

the machine at the throttle position for a distance of about 10km after which the spark plug and

piston crown should be inspected for color and appearance.

●

The mixture can be made”richer”or”leaner”in three ways:namely.by altering main jet.jet needle

and pilot jet.effectiveness of these ways depends on the throttle position.as shown in this chart.

Note: If the machine is tested at 1/2throttle resulting in a color and appearance indicating a mixture

that is too rich or too lean.perform adjustment by means of jet needle.

- 27 -