fuel consumption.

Service limit

0.05mm

CYLINDER

Decarbon the exhaust port and the upper part of the cylinder.

taking care not to damage the cylinder wall surface.

The wear of the cylinder wall is determined form diameter

reading taken at 20mm from the top of the cylinder with a

cylinder gauge.if the wear thus determined exceeds the limit

indicated below,rework the bore to the bore to the next oversize

by using a boring machine or replace the cylinder with a new

one. oversize pistons are available in two sizes:0.5mm and

1.0mm oversizes.

After reworking the bore to an oversize.be sure to chamfer the

edges of ports and smooth the cham-fered edges with emery

paper.to chamfer,use a scraper,taking care not to nick the wall

surface.

Note: Minor surface flaws on the cylinder wall due to seizure

or similar abnormalities can be corrected by grinding the flaws

off with finegrain emery paper.if the flaws are deep grooves

or otherwise persist,the cylinder must be reworked with a boring

machine to the next oversize.

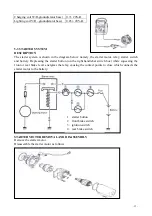

PISTON

CYLINDER TO PISTON CLEARANCE

Cylinder-to-piston clearance is the difference between piston

diameter and cylinder bore diameter. be sure to take the miked

diameter at right angles to the piston pin.the value of elevation

○

A is prescribed to be 14mm from the skirt end.

As a result of the above measurement,if the piston-to-cylinder

clearance exceeds the following limit.overhaul the cylinder

and use an oversize piston.or replace both cylinder and piston.

The measurement for the bore diameter between the intake and

exhaust ports sides will be made at 20mm from the cylinder top

surface.

STD

Service

limit

Cylinder to piston

0.060-0.070

0.120

DE-CARBONIZING

De-carbon the piston and piston ring grooves,as shown in Fig.After cleaning the grooves,fit the

- 20 -