Caution:

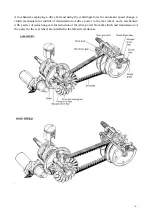

Once remove the movable drive face, rollers provided inside he drive face may be dislocated and

disassembly of the drive face be needed.

Remove the starter driven gear and key.

Note:

When reinstalling the starter driven gear, align the key groove

with the key.

Using the rotor holder, remove the rotor securing nut.

Tightening torque

35-43N.m

(3.5-4.3 kg .m )

using the crankcase separating tool, remove the rotor from

the crankshaft.

Remove the red valve assembly

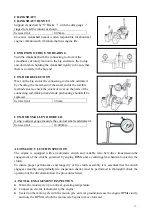

Remove the crankcase securing screws.

Using the crankcase separating tool and attachment, remove

the right crankcase from the left one.

Tap the left end of the crankshaft with plastic hammer and

remove the crankshaft from the left grankcase.

Remove the oil pump driven gear and thrust washer

- 14 -