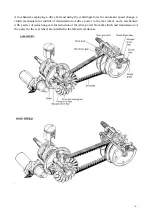

CRANKSHAFT

CRANKSHAFT RUNOUT

Support crankshaft by”V”blocks

○

2

,with the dial gauge

○

3

rigged to read the runout as shown.

Service limit

0.05mm

Excessive crankshaft runout is often responsible for abnormal

engine vibration.such vibration shortens engine life.

CONDITION OF BIG END BEARING

Turn the crankshaft with the connecting rod to feel the

smoothness of rotary motion in the big end.move the rod up

and down while holding the crankshaft rigidly to be sure that

there is no rattle in the big end.

CON-ROD DEFLECTION

Wear on the big end of the connecting rod can be estimated

by checking the movement of the small end of the rod.this

method can also check the extent of wear on the parts of the

connecting rod,crank pin and crank pin bearing should all be

replaced.

Service limit

3.0mm

CON-ROD SMALL END BORE I.D.

Using a caliper gauge,measure the con-rod small end diameter.

Service limit

14.040mm

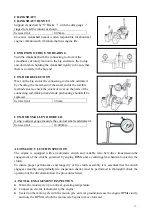

AUTOMATIC CLUTCH INSPECTION

The engine is equipped with an automatic clutch and variable ratio belt drive transmission.the

engagement of the clutchs governed by enging RPMs and a centrifugal mechanism located in the

clutch.

To insure proper performance and longevity of the clutch assembly it is essential that the clutch

engages smoothly and gradually.two inspection checks must be performed to thoroughlt check the

operation of the drivetrain.follow the procedures listed.

A .INITIAL ENGAGEMENT INSPECTION

●

Warm the motorcycle up to normal operating temperature.

●

Connect an electric tachometer to the engine.

●

Seated on the motorcycle with the motorcycle on level ground,increase the engine RPMs slowly

and note the RPM at which the motorcycle begins to move forward.

- 17 -