37

AC TIG Welding - AC Wave Balance Control

Razor

32OAC/DC

TIG-MMA

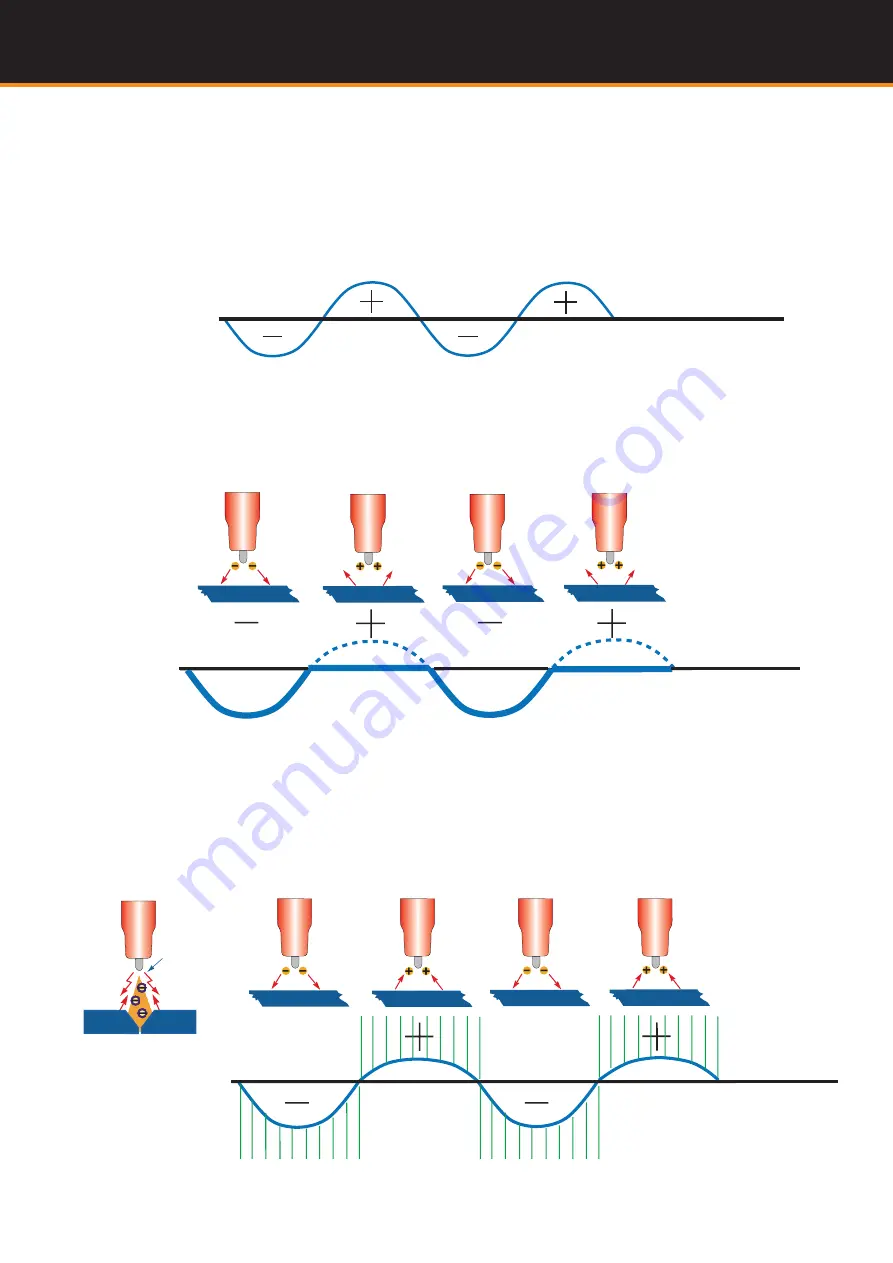

The use of Alternating Current enables us to TIG weld non-ferrous alloys like Aluminium, Magnesium and Aluminium

Alloys. These materials have an insulating surface oxide layer that melts at a higher temperature than the base metal

beneath, making it difficult to weld if the oxides are not removed. AC welding current is ideal because the nature of

the AC wave form assists in breaking the surface oxide layer, often referred to as the “cleaning action”. AC current

has a cycle where the flow changes direction between Electrode Negative (-, direct polarity) and Electrode Positive (+,

reverse polarity). The Electrode Positive phase of this cycle breaks down the surface oxides while the direct polarity

Electrode Negative phase melts the base material and provides weld penetration.

There are inherent problems that come with AC TIG arc rectification: arc stutter, arc wandering and arc stoppage.

These problems typically occur during the transition between positive and negative phase of the alternating cycles.

The current reduces by as much as 30% during the electrode positive phase and there is a resistance of the electron

flow during this half cycle (rectification). The lack of current flow during this half cycle makes the AC arc unstable.

In older welding machines, to overcome this lack of flow during the Electrode Positive phase of the cycle, high-fre-

quency (HF) voltage is generated and fed continually into the welding circuit. The HF energizes the arc and maintains

arc stability during the Electrode Positive phase of the AC cycle. Although the welding arc is maintained, less current

flows during the Electrode Positive phase of the AC cycle, resulting in an unbalanced wave form.

UNBALANCED WAVE FORM

+

_

HF

30%

30%

current

reverse polarity

straight polarity

current

current

reverse polarity

direct polarity

reverse polarity

direct polarity

30%

30%

current

reverse polarity

direct polarity

Summary of Contents for RazorWeld Razor TIG320 ACDC

Page 7: ...7 Electrical Schematic Diagram Razor32OAC DC TIG MMA...

Page 54: ...54 NOTES...

Page 55: ...55 NOTES...